Công ty TNHH Máy móc bột Thanh Đảo Epic là một chuyên gia nhà sản xuất of powder processing equipment. Our products mainly include: powder grinding equipment, classification equipment, modification equipment Và thiết bị phụ trợ liên quan.

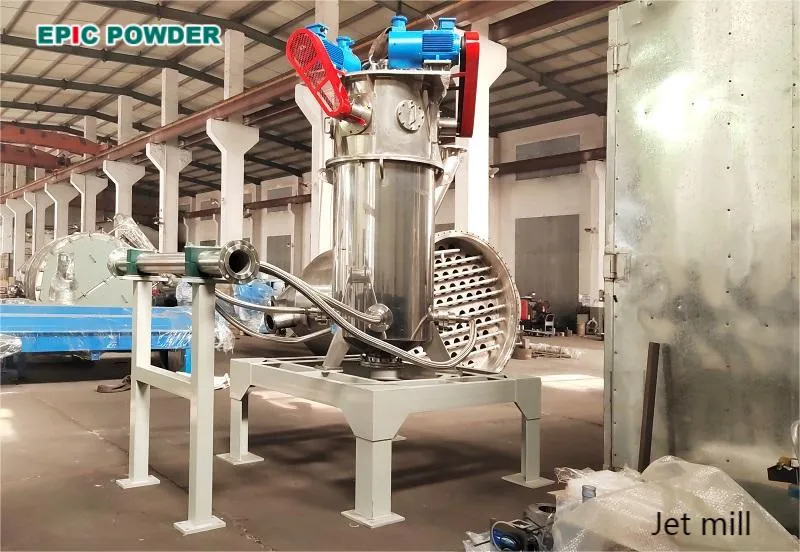

Among the products, our grinding equipment includes: máy xay công nghiệp, jet mill, máy nghiền bi, air classifier mill, vibration mill, etc. Based on our company’s many years of practical production experience and feedback from consumers, we have made a general comparison and selection guide for roller mill, jet mill and ball mill. We hope it can be of some help to powder processing enterprises in the selection of the three mills.

Comparison of the characteristics of the three

| Parameter | Máy nghiền trục lăn | Jet mill | máy nghiền bi |

| Grinding principle | Roller-ring extrusion and shearing | High-speed airflow impact and collision | Steel balls/ceramic balls impact grinding |

| Energy consumption | Low (30-50% lower than ball mill) | Very high (2~3 times that of roller mill) | High |

| Heat-sensitive material | Partially applicable (air cooling temperature control) | Very suitable (low temperature grinding) | Not applicable (easy to heat up) |

| Metal contamination risk | Low | No | High |

| Maintenance costs | Medium (replace the roller sleeve regularly) | Low (no wear of moving parts) | High (frequent liner/balls change) |

| Application areas | Non-metallic minerals, building materials, chemicals | Medicine, lithium batteries, high-purity materials | Mining, cement, ceramics |

Key factors for selection

· Material characteristics

— High hardness materials (Mohs hardness ≥ 7)

✖ Roller mill (roller wears quickly)

✔ Jet mill (non-contact grinding), or ball mill (ceramic lining)

Examples: Silicon carbide, corundum

— Heat-sensitive/sticky materials

✔ Jet mill (low temperature, no adhesion)

✖ Ball mill (severe temperature rise), roller mill should be based on actual conditions

Examples: Vitamins, resins

· Product fineness

— Ultra-fine powder (D97 ≤ 5μm)

✔Preferred jet mill (narrow particle size distribution)

— Medium fine powder (10~100μm)

✔ Roller mill (most cost-effective)

— Coarse powder(>100μm)

✔Ball mill (strong adaptability)

· Capacity and cost

— Small-batch high-value-added products

✔ Jet mill (high precision, suitable for medicine/lithium battery)

— Large-scale continuous production

✔ Roller mill (low energy consumption) or Ball mill (large production capacity)

— Limited budget

✔ Roller mill or ball mill

Typical industry application recommendations

| Industry | Preferred equipment | Alternatives | Reason |

| Lithium battery materials | Jet mill | Roller mill+air classifier | Ultra-fine and pollution-free powder is required |

| Cement slag powder | Máy nghiền trục lăn | Vertical mill | Energy saving and specific surface area meets the standard |

| Pharmaceutical intermediates | Jet mill | Vibration mill | Low temperature and no metal pollution |

| Ceramic glaze | máy nghiền bi | Máy nghiền trục lăn | More coarse grinding needs with low cost |

To sum up what has been said above, it is: Ultra-fine high-purity selecting jet mill, large-scale energy saving selecting roller mill, cost-effective coarse grinding selecting ball mill.

For Milling Equipment Selection & Powder Processing Solutions

✭If you have any inquiries about mill selection, please contact Epic Powder. Our experts are committed to providing comprehensive answers.

✭If you require powder grinding equipment or other powder processing systems, Epic Powder offers end-to-end support, including:

✔ Pre-project technical consultation & solution design

✔ Equipment installation & commissioning

✔ Operator training programs

✔ Equipment maintenance & technical upgrades

Contact Epic Powder, and let our professional equipment help your powder processing be more efficient and energy-saving.