Giới thiệu

What is powder surface modification technology? It refers to the technology that uses physical, chemical or mechanical methods to treat the surface or interface of powder materials, purposefully changing the physical and chemical properties of powder material surface to meet the needs of different application fields.

Modification mechanism

From the perspective of modification mechanisms, calcium carbonate (CaCO₃) surface modification can be broadly classified into two categories: chemical interactions and physical interactions.

Surface chemical interaction:

– Functional group substitution (e.g., hydroxyl group replacement)

– Polymerization & grafting (e.g., in-situ polymerization, polymer coating)

– Hydrolysis (e.g., silane coupling agent reactions)

Surface physical interaction:

– Adsorption (e.g., surfactant or fatty acid adsorption)

– Coating/encapsulation (e.g., stearate layer formation)

– Wetting (e.g., improved dispersion in polymer matrices)

When the filler is completely wetted, physical adsorption will occur on the high-energy surface of calcium carbonate, and the energy of this adsorption is higher than the cohesive bonding strength of the plastic.

Modification methods

Currently, the mainstream methods for calcium carbonate (CaCO₃) surface modification include:

· Coupling agent modification (e.g., silane, titanate, or aluminate coupling agents)

· Stearate modification (e.g., sodium stearate, calcium stearate)

· Phosphate ester modification

· In-situ polymerization modification

· Surface polymer grafting modification

However, due to cost efficiency and process simplicity, the most commonly used industrial methods are coupling agent modification and fatty acid salt modification (particularly stearates).

Key factors in modification effectiveness

Coupling agent modification: To enhance chemical bonding with organic matrices (e.g., plastics, rubber) through covalent attachment of functional groups.

Fatty acid salt modification: To improve dispersibility and hydrophobicity (e.g., in coatings and inks) via physical adsorption of surfactant layers.

Purpose of surface modification

Generally speaking, the surface modification of calcium carbonate mainly aims to achieve the following objectives:

(1) Reduce the cohesive force between particles and improve the dispersibility of calcium carbonate;

(2) Enhance the surface activity of calcium carbonate;

(3) Improve the compatibility of calcium carbonate with other substances;

(4) Increase the acid resistance of calcium carbonate;

(5) Prepare calcium carbonate with specific crystal forms for different industries.

From the perspective of the development of modification technologies, improving the surface modification effect, reducing the cost of surface modification, developing green modifiers, and optimizing modification equipment are all important development directions.

Application of modified calcium carbonate

After surface modification, calcium carbonate (CaCO₃) exhibits significantly improved compatibility with matrix materials, enhanced dispersibility, and superior interfacial bonding strength, thereby expanding its applications across multiple industries. Below are the key application fields of modified calcium carbonate:

Plastics industry/Rubber industry/Coatings & inks/Paper-making industry/Adhesives & sealants/Pharmaceuticals & food/Environmental & construction/Advanced composites

Phần kết luận

Through optimizing the inter-facial performance, modified calcium carbonate has achieved a leap from a traditional filler to a functional material with high-added value, and it has become an indispensable multifunctional additive in modern industry.

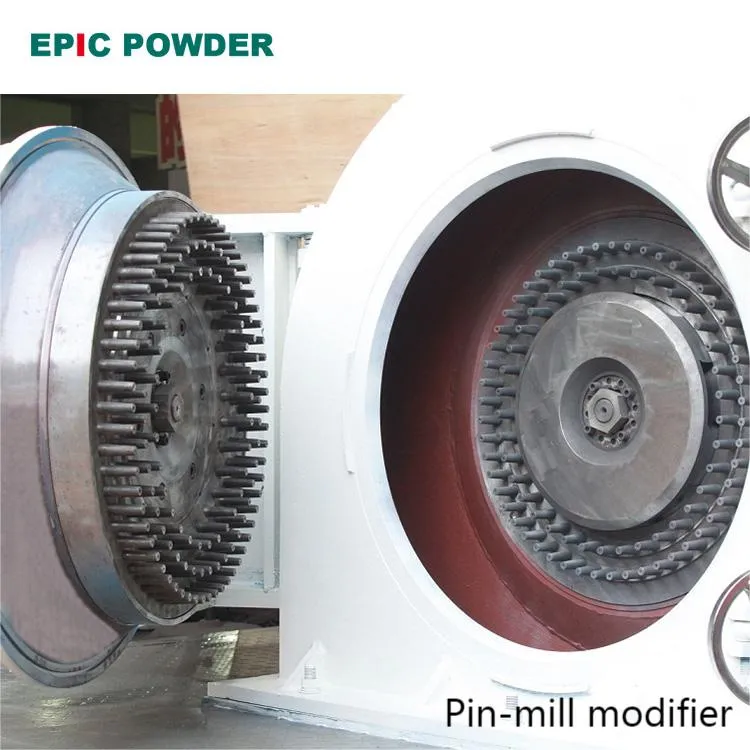

Công ty TNHH Máy móc bột Epic Thanh Đảo là một chuyên gia nhà sản xuất of powder processing equipment. Our products mainly include: powder grinding equipment, classification equipment, modification equipment and related auxiliary equipment. Among them, the powder modification equipment includes: bộ điều chỉnh pin-mill, three-rotor-mill modifier Và bộ điều chỉnh tuabin-mill. They have high modification rate, especially pin-mill modifier, modification rate can achieve 99% , which has been widely recognized by consumers.

If you have demands for modification equipment or other powder processing equipment, please contact Epic Powder. We’ll provide comprehensive support as below:

✭ Pre-project phase: Technical consultation & customized solution design

✭ Implementation: Equipment installation & commissioning with operator training

✭ After-sales service: Maintenance, upgrades, and continuous technical support

Liên hệ Epic Powder, and Let our specialized equipment empower your powder processing – for higher efficiency and more energy-saving.