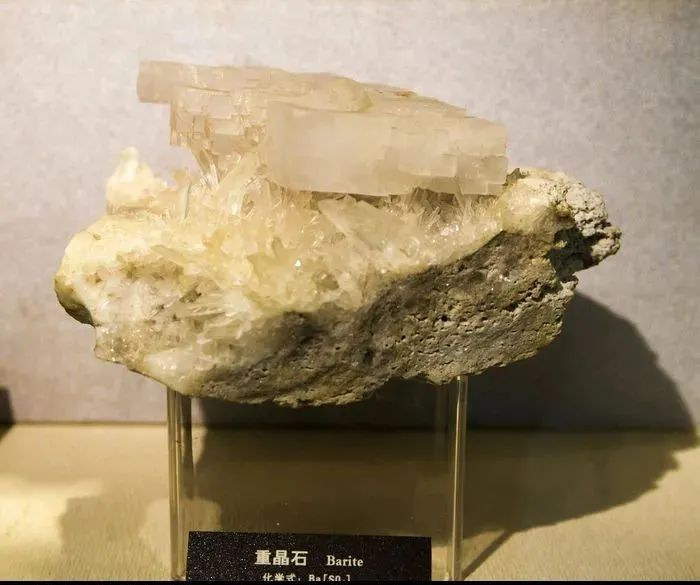

Barit là khoáng chất phổ biến nhất của bari, và thành phần chính của nó là bari sunfat. Nó thường có màu trắng và sáng bóng, nhưng cũng có thể có màu xám, đỏ nhạt hoặc vàng nhạt do tạp chất. Barit có tính chất hóa học ổn định, không độc hại và không tan trong nước hoặc axit clohydric. Bằng cách xử lý quặng barit thô thông qua nghiền, phân loại và các bước khác, có thể thu được bột barit cấp hóa học. Để hiểu sâu hơn, tiếp theo, chúng ta sẽ nói về ứng dụng và biến đổi bột barit.

Ứng dụng của bột barit

Bột barit là một loại nguyên liệu khoáng phi kim loại quan trọng có phạm vi ứng dụng rộng. Các lĩnh vực ứng dụng chính của nó là công nghiệp dầu mỏ và công nghiệp hóa chất. Trong công nghiệp dầu mỏ, bột barit có thể đóng vai trò là chất làm tăng trọng lượng cho bùn khoan dầu khí; Trong công nghiệp hóa chất, nó có thể đóng vai trò là nguyên liệu để sản xuất nhiều loại sản phẩm hóa học chứa bari, chẳng hạn như bari cacbonat, bari sunfat và bari oxit.

Ngoài ra, bột barit cũng có thể được sử dụng trong ngành sơn để tăng độ dày, độ bền và độ bền của sơn. Hơn nữa, trong ngành cao su và nhựa, bột barit có thể cải thiện độ cứng, khả năng chống mài mòn và khả năng chống lão hóa của các sản phẩm cao su và nhựa.

Biến tính barit bột

Do bề mặt của bột barit ưa nước, trong khi hầu hết các vật liệu polyme lại kỵ nước nên bột barit khó có thể phân tán đều trong vật liệu polyme, điều này ảnh hưởng đến hiệu suất toàn diện của vật liệu tổng hợp. Để cải thiện hiệu suất và mở rộng phạm vi ứng dụng, bề mặt của bột barit phải được biến đổi.

Hiện nay, phương pháp được sử dụng phổ biến nhất để biến tính bột barit là biến tính lớp phủ bề mặt.

Sửa đổi lớp phủ bề mặt bột barit là công nghệ tạo lớp phủ ổn định và đồng nhất trên bề mặt hạt barit bằng phương pháp vật lý hoặc hóa học để thay đổi tính chất bề mặt của nó. Bề mặt của bột barit đã sửa đổi là ưa nước và kỵ dầu, điều này có thể cải thiện khả năng phân tán và ái lực của nó trong vật liệu composite.

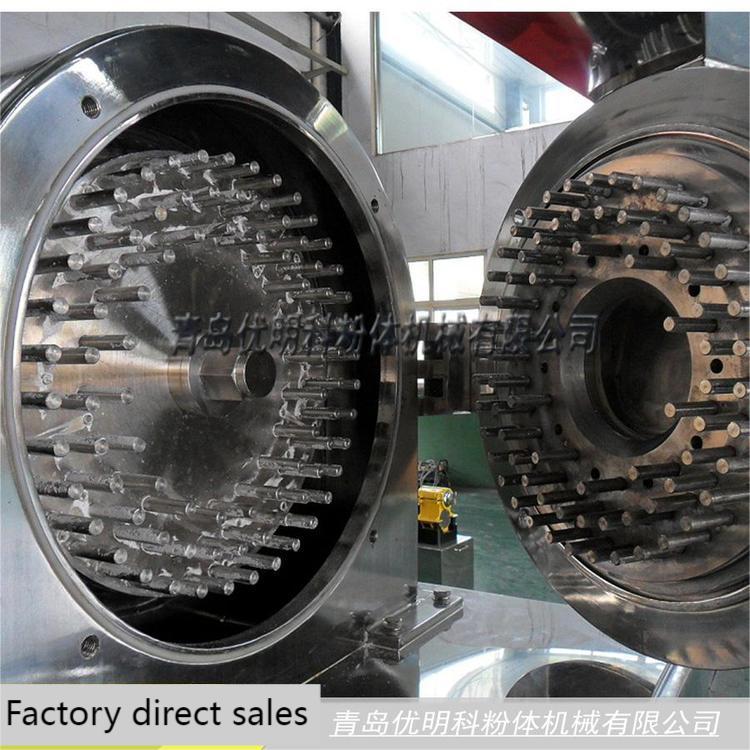

Công ty TNHH Máy móc bột Qingdao Epic là một nhà sản xuất chuyên sản xuất máy móc bột. Thiết bị sửa đổi lớp phủ bề mặt là một trong những sản phẩm của chúng tôi, bao gồm ba dòng: bộ điều chỉnh pin-mill, bộ điều chỉnh tuabin-mill, Và máy biến áp ba rôto. Các thiết bị này có thể hoàn thành quá trình phủ và tạo màng trong thời gian ngắn, với hiệu suất tuyệt vời và mức tiêu thụ năng lượng thấp, đặc biệt là loại máy nghiền bi, rất được khách hàng ưa chuộng.

Các sản phẩm chính của chúng tôi bao gồm:

– Nhà máy: máy xay công nghiệp, máy nghiền bimáy nghiền phân loại bằng khí (ACM), máy nghiền phản lực và máy nghiền tuabin, v.v.

– Không khí Bộ phân loại: bao gồm bốn loạt: HTS, ITC, MBS và CTC .

– Chất điều chỉnh lớp phủ bề mặt: bộ điều chỉnh máy nghiền chốt, bộ điều chỉnh máy nghiền tuabin và bộ điều chỉnh máy nghiền ba rôto, v.v.

– Thiết bị phụ trợ: tủ điều khiển, máy hút bụi Và thang máy xô, vân vân.

– Khách hàng có thể tùy chỉnh sản phẩm theo nhu cầu thực tế. Một khách hàng, một thiết kế.

Nếu bạn có nhu cầu liên quan đến việc sửa đổi thiết bị hoặc các sản phẩm khác từ Sử thi Thanh Đảo, liên hệ với nhân viên của chúng tôi trực tiếp, chúng tôi luôn sẵn sàng phục vụ bạn.

Dưới đây là các sản phẩm của Qingdao Epic để bạn tham khảo.