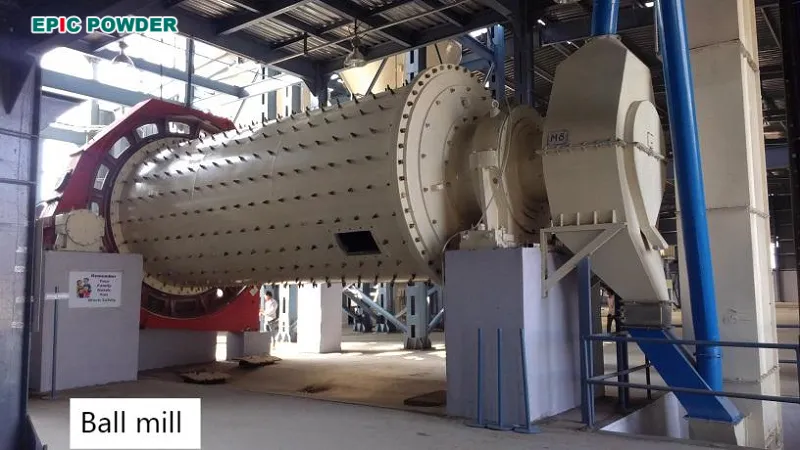

گیند کی چکی is an important powder grinding equipment. It can achieve fine grinding of materials. The maintenance and inspection of ball mill is an important task. They directly affect the operation efficiency and service life of the ball mill.

As a ball mill supplier, چنگ ڈاؤ ایپک پاؤڈر مشینری کمپنی لمیٹڈ has always been guided by the concept of being responsible to customers. In addition to attaching great importance to the quality and performance of ball mill, Epic Powder also places a high premium on the maintenance and inspection of ball mill, and to ensure smooth production for our customers, we have summarized maintenance and inspection guidelines for ball mill as a reference.

The Maintenance and Inspection of Ball Mill

- All lubricating oil should be drained, and replaced with new oil after the mill has in operation for one month. Subsequently, the oil should be changed every 6 months.

- Check the lubrication condition and oil level of each lubrication point at least once every 4 hours.

- When the mill is in operation, the temperature rise of the lubricating oil in the main bearing shall not exceed 55℃.

- When the mill is operating normally, the temperature rise of the transmission bearing and the gearbox shall not exceed 55℃, and the maximum temperature shall not exceed 60℃.

- The girth gear and pinion gear should operate smoothly without abnormal noise. The clearance should be adjusted timely if necessary.

- The ball mill should operate smoothly without strong vibration.

- There should be no abnormal fluctuation in motor current.

- All connecting fasteners should be free of looseness, and there should be no oil leakage, water leakage, or mineral leakage at the joint surfaces.

- Grinding balls should be added timely according to the wear condition.

- When the cylinder liner is worn by 70% or there are cracks 70mm long, it should be replaced.

- When the liner bolts are damaged and cause the liners to loosen, they should be replaced.

- When the main bearings are severely worn, they should be replaced.

- The pinion gear should be replaced if it is severely worn.

- Loose or damaged anchor bolts should be repaired timely.

- If any abnormal situation is found, the mill should be stopped and repaired immediately.

In the operation of the ball mill, in order to avoid failures, timely and accurate handling of faults and taking preventive measures is necessary.

If you have any questions regarding ball mill, please contact Epic Powder. We will spare no effort to answer them for you. If you are in need of ball mill products, you are also welcome to get in touch with Epic Powder. Our company has a professional team to follow up throughout the process. We can provide not only high-quality products, but also a full range of services, from technical consultation and solution design, to equipment installation and commissioning, operator training, and equipment maintenance and technical upgrades.

Contact Epic Powder, and let our professional equipment help your powder processing be more efficient and energy-saving.