تعارف

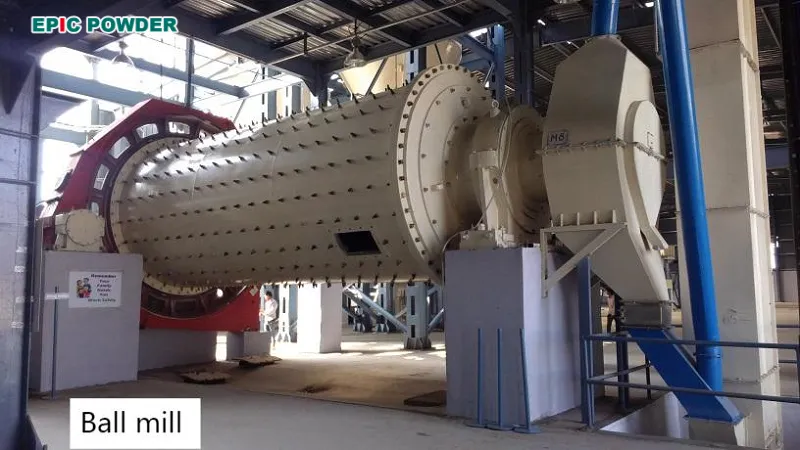

As an extremely crucial equipment in the material grinding process, ball mill is widely used in many industries, such as mineral processing, building materials, and chemical engineering. Its working principle is to drive the movement of grinding media (such as steel balls, ceramic balls, etc.) through the rotation of the cylinder, to grind the materials inside the cylinder.

Among the numerous operating parameters of a ball mill, the rotational speed is a decisive factor for the grinding process. Changes in rotational speed not only alter the motion state of the grinding media, but also significantly affect grinding efficiency, particle size distribution, and energy consumption. The influence of rotational speed is of great significance for optimizing the operation of ball mill, to improve production efficiency and reduce production costs.

The influence of rotational speed on the grinding process

The rotational speed of ball mill is usually expressed as a percentage of the critical rotational speed (the ratio of the actual rotational speed to the critical rotational speed). The critical rotational speed (Nc) refers to the rotational speed at which the grinding media just adheres to the inner wall of the cylinder and rotates without falling.

The calculation formula is: Nc = 42.3/√D (unit: r/min), where D is the inner diameter of the cylinder (in meters).

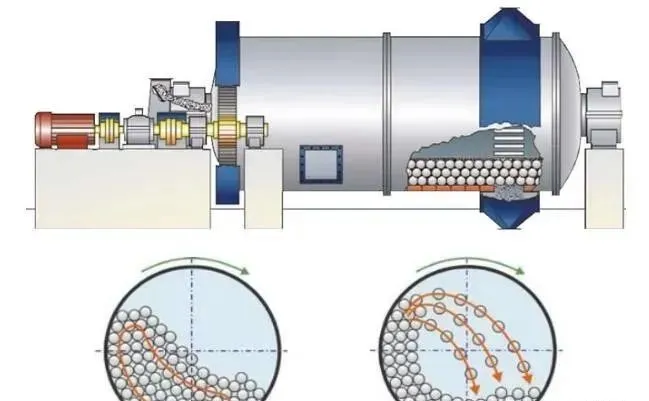

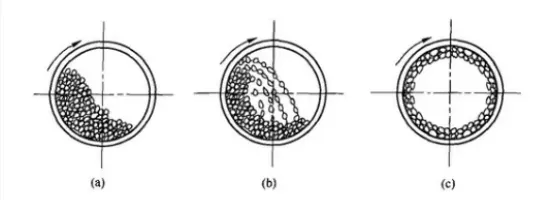

According to the differences in rotational speed, the movement of the grinding media can be divided into three states.

Low rotational speed (< 60% of the critical speed Nc)

Movement of the media: It is mainly in a cascading state, with strong grinding effect and weak impact force.

Effect: It is suitable for fine grinding, but the efficiency is relatively low and the energy consumption is high.

Problem: It is likely to cause the material to accumulate, forming a “stagnant layer”, which reduces the uniformity of grinding.

Appropriate rotational speed (65% – 80% of Nc)

Movement of the media: It is a combination of cataracting and cascading, with a balanced impact and grinding effect.

Effect: It has the highest grinding efficiency and reasonable energy consumption, and it is the commonly used range in actual operation.

Optimal point: It is usually 76% of Nc (the theoretical optimal value is approximately 70.7%, while it is slightly higher in practice due to factors such as friction).

High rotational speed (> 80% of Nc)

Movement of the media: The media experience centrifugation, rotating closely along the inner wall of the cylinder and losing its impact and grinding functions.

Effect: The grinding effect almost stops, the energy consumption surges sharply, and the wear of the liner plates and the media is aggravated.

Problem: It may cause equipment vibration and even failures.

a: Cascading type

b: Cataracting type

c: Centrifugal type

نتیجہ

The rotational speed of the ball mill is a crucial factor affecting the grinding process. Reasonably controlling the rotational speed to keep the grinding media in an ideal motion state is of great significance for improving the grinding efficiency, reducing energy consumption, and extending the service life of the equipment. In actual production, factors such as the characteristics of the materials and the requirements of the products should be taken into account to optimize the rotational speed setting of the ball mill, so as to achieve efficient, energy-saving, and stable grinding operations.

چنگ ڈاؤ ایپک پاؤڈر مشینری کمپنی لمیٹڈ ایک پیشہ ور ہے کارخانہ دار specializing in powder processing equipment, with decades of production experience and technical expertise.

Our products include:

Grinding equipment: گیند کی چکی, رولر مل, jet mill, air classifier mill, turbo mill, etc.

Classifying equipment: Include 5 types of air classifier– ایچ ٹی ایس, آئی ٹی سی, CTC, MBS and TDC.

Surface modification equipment: Pin-mill modifier, تین روٹر مل موڈیفائر اور ٹربو مل موڈیفائروغیرہ

Auxiliary equipment: Control cabinet, bag filter, سکشن پرستاروغیرہ

Ball mill is one of our company’s main grinding equipment. It has excellent performance and reasonable price, and has received favorable feedback from numerous customers over the years. If you are interested in our ball mill or other powder processing equipment, please contact us. Our company has a professional team to follow up throughout the whole process, from technical consultation, solution design to equipment installation and commissioning, operator training, as well as equipment maintenance and technical upgrading.

Contact Epic Powder, and Let our specialized equipment empower your powder processing –for higher efficiency and more energy-saving.