1. Кереш сүз

Шар тегермәне сатып алганда, кулланмада җентекле техник параметрлар булачак, алар чыгару диапазонын үз эченә ала. Гадәттә, туп комбинаты чыгару башта нормаль булып калачак, ләкин берникадәр вакыт эшләгәннән соң, чыгару түбән булырга мөмкин. Алай булгач, нинди сәбәпләр бар чыгару шар тегермәне?

2. Туп тегермәненең аз чыгарылу сәбәпләре

✱ Тозу шар тегермәне

Туп тегермәне җитештерү түбән һәм түбән булгач, туп тегермәненең туенганы турында уйлануның беренче сәбәбе - ул тегермән җитештерүенә тәэсир итүче гаепле.

Туп тегермәнен туендыруның берничә сәбәбе бар. Сәбәпләр үз эченә ала: бик күп туклану. ②ардер һәм зуррак азык. Feed азыкның дымлылыгы. Steel корыч тупларның акылсыз классификациясе. Partition бүлек тактасын блоклау.

✱ Бик озын тарту вакыты

Тегермән вакыты бик озын булса, бу азыкның артык җиренә китерергә мөмкин, бу бик нечкә кисәкчәләргә китерә. Бу шар комбинатының эшкәртү сыйфатын киметәчәк, шуның белән җитештерүне киметәчәк.

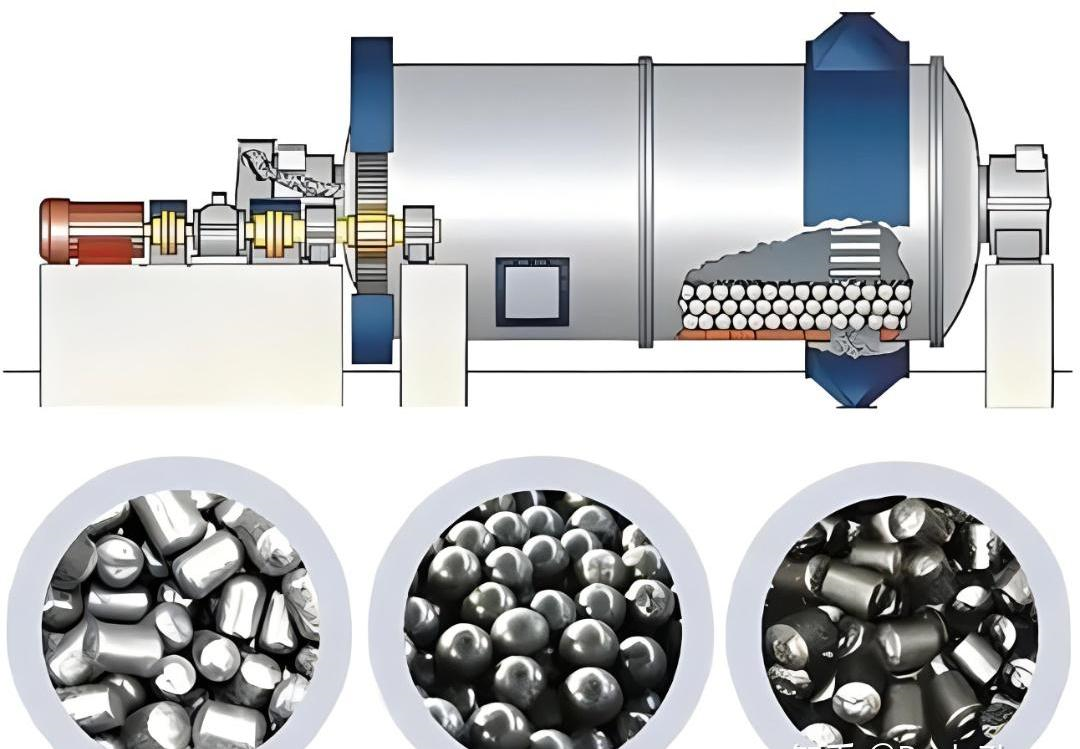

✱ Корыч тупларны вакытында кушмау

Тегермән эффекты да, шар тегермәне чыгару да корыч шарлар белән чикләнә. Озак вакыт тарту һәм палатада тәэсир аркасында корыч шарлар тузачак, шуңа күрә корыч тупларны вакытында өстәү шар тегермәне чыгаруны тәэмин итүдә мөһим фактор.

✱ Палатада артык югары температура

Палатада температура артык югары булганда, материал асфальтка ябышачак, китереп чыгара агломерация. Бу тарту эффективлыгын киметәчәк һәм энергия куллануны арттырачак. Шул ук вакытта, югары температура җиһазның куркынычсыз эшләве өчен үткәргеч булмас.

✱ Equipmentиһазларның эшләмәве

Туп тегермәне эшләгәндә, ниндидер уңышсызлык килеп чыкса, мәсәлән, подшипник яки каеш зарарланса, туп тегермәненең аз чыгарылышына китерәчәк.

3. Йомгаклау

Әгәр сезнең шар комбинатыгыз түбәнәя бара бара икән, сез югарыдагы сәбәпләрне тикшерә аласыз. Икътисади өстенлекләрне яхшырту өчен шар тегермәненең эффективлыгына һәм чыгарылышына тәэсир итүче проблеманың тамырын табу бик мөһим.

Daиндао Эпик Порошок Машиналар ООО. а җитештерүче порошок эшкәртү җиһазлары җитештерүдә махсуслашкан.

Аның продуктлары:

– Тегермән: шар тегермәне, ролик тегермәне, реактив тегермән, һава классификатор комбинаты, тибрәнү комбинаты һәм тәэсир тегермәне һ.б.

– Классификатор: һава классификаторларының дүрт сериясе: ХТС, ITC, MBS һәм CTC.

– Модификатор: тегермән үзгәртүчесе, турбо тегермәне модификаторы һәм өч роликлы модификатор һ.б.

– Ярдәмче җиһаз: контроль шкаф, тузан җыючы һәм сорау җанатары һ.б.

- Клиентлар шулай ук җиһазларны үз ихтыяҗлары буенча көйли алалар, бер клиент бер дизайн.

Әгәр сез шар тегермәне яки башка җиһазлар белән кызыксынсагыз Daиндао эпосы, зинһар персонал белән элемтәгә керергә турыдан-туры, алар һәрвакыт сезнең хезмәттә.

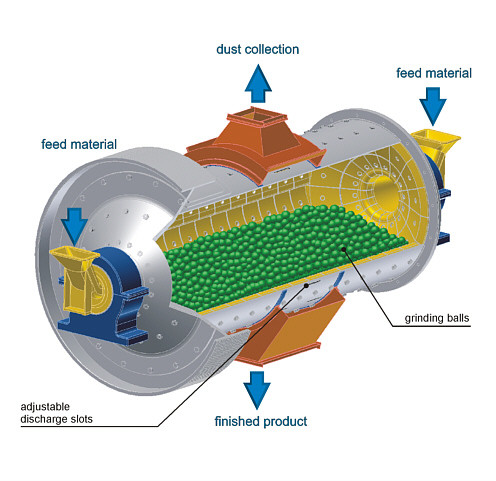

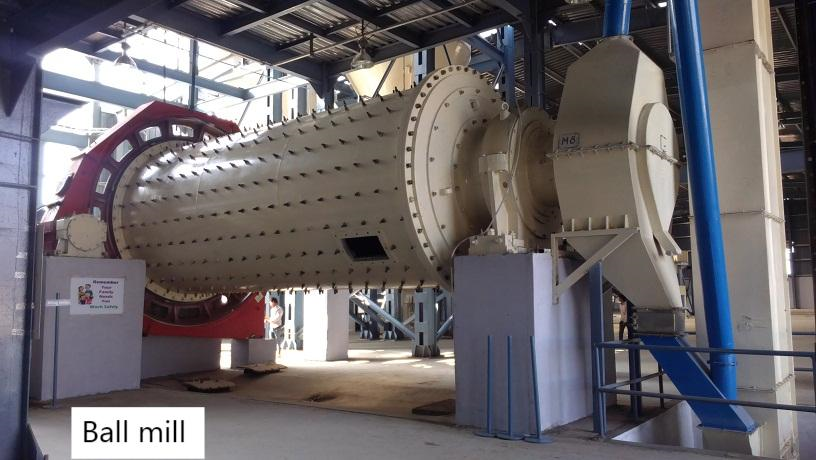

Түбәндә белешмә өчен daиндао эпосыннан алынган фотолар.