Kaolin, named after Gaoling Village in Jingdezhen, Jiangxi, China, is the “soul raw material” of ceramics. Its main component is kaolinite (chemical formula Al₂[(OH)₄/Si₂O₅]), and it is formed by the weathering of silicate minerals such as feldspar. Kaolin has a fine and white texture, with plasticity and fire-resistance. From the “binary formula” that revolutionized ceramic technology in the Song Dynasty to its application in modern paper-making, chemical industry, and aerospace materials, kaolin has always been the “hidden champion” of the industry.

Six technological characteristics of kaolin

1. Whiteness and brightness: determine its color purity

Natural whiteness: Whiteness after drying at 105°C. Impurities (such as Fe₂O₃ and MnO₂) will make it appear yellow, brown.

Calcined whiteness: The whiteness after calcination at 1300℃directly affects the glossiness of ceramics and coatings. The whiteness of high-quality kaolin after calcination can be > 90%.

Brightness: Reflectivity under 4570Å wavelength light, which is particularly important in paper-making industry.

2. Particle size distribution: the “gold standard” for industrial applications

The finer the particles, the stronger the plasticity and suspension. For example, the United States requires that more than 90% of the kaolin particles used in coatings should be <2μm.

3. Plasticity: The “magic” of ceramic molding

The plasticity index (difference of moisture content between liquid limit and plastic limit) and index (resistance to deformation) are the core parameters. Strong plasticity kaolin (index > 15) can be easily shaped and is not prone to cracking.

4. Bonding and viscosity: The “adhesive” of industrial formulas

Bonding refers to the strength after mixing with non-plastic materials (such as quartz sand). The higher the sand content, the stronger the bonding.

Viscosity affects the fluidity of slurry. Paper-making coatings require a viscosity as low as 0.5 Pa·s (slow speed coating).

5. Drying and sintering performance: the transformation from clay to porcelain

Drying shrinkage: Linear shrinkage rate is 3%-10%. Excessive shrinkage can easily cause cracking of the ceramic body.

Refractoriness: The refractoriness of pure kaolin can reach 1700℃, and impurities will significantly reduce its high temperature resistance.

6. Adsorption and insulation: potential for cross-border applications

Kaolin has a weak ability to absorb ions, but after modification, it can be used in environmental protection fields (such as wastewater treatment).

The main application of kaolin

— Ceramic industry (accounting for about 40%)

Daily-use porcelain, building ceramics, and electrical porcelain all rely on the properties of molding and high-temperature resistance of kaolin.

— Paper-making and coatings industries (accounting for about 30%)

As a filler and coating, kaolin can improve the gloss and smoothness of paper.

— Refractory materials

Refractory materials like refractory bricks and crucible need to withstand high temperatures above 1600℃, and kaolin is the core raw material.

— New materials field

Modified kaolin is used for rubber reinforcement and plastic filling, and nano kaolin is used in biomedicine.

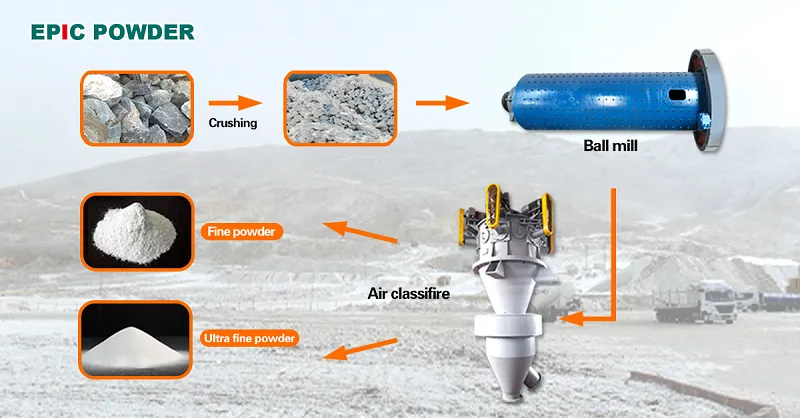

In actual applications, when kaolin is used in high-end fields, such as: paper-making and high-performance ceramics, it needs to be ground and graded. While, when it is used in low-end fields, such as building ceramic bodies, the raw ore can be used directly.

The bilyalı değirmen + hava sınıflandırıcı tarafından üretildi Qingdao Epic Toz Makineleri Co., Ltd. is suitable for grinding and classifying kaolin in high-end applications. Our ball mill + classifier production line is an internationally cutting-edge non-metallic mineral powder processing production line. It is with high operating efficiency, competitive price and high reputation among customers.

Our products include: ball mill, air classifier mill, roller mill, jet mill, various air classifiers, surface coating and modification equipment Ve ilgili yardımcı ekipman.

If you have relevant needs for our ball mill+air classifier, or other products, please feel free to personelimizle iletişime geçin doğrudan, her zaman hizmetinizdeyiz.