1. Giriş

Kağıt yapım endüstrisinde, hammadde seçimi kağıdın kalitesi, performansı ve üretim maliyetinde önemli bir rol oynar. Birçok katkı maddeleri, kaolin benzersiz fiziksel ve kimyasal özellikleri nedeniyle vazgeçilmez hammaddelerden biri haline gelmiştir. Kaolin kağıt kalitesini iyileştirmeye, üretim sürecini optimize etmeye ve kağıt yapım endüstrisinin sürdürülebilir gelişimini desteklemeye yardımcı olabilir.

Peki, kaolinin kağıt yapım endüstrisindeki özel işlevleri nelerdir? Öncelikle temel özelliklerine bir göz atalım:

2. Kaolinin temel özellikleri

Kaolin metalik olmayan bir mineraldir. Bir tür kil esas olarak kaolinit kil mineralinden oluşur. Beyaz ve narin görünümü nedeniyle kaolin aynı zamanda dolomit olarak da adlandırılır. Mükemmel plastisite ve yangına dayanıklılık özelliklerine sahiptir. Kaolinin geniş bir uygulama alanı vardır, esas olarak kağıt yapımında, seramiklerde ve refrakter malzemelerde kullanılır ve ikinci olarak kaplamalarda, kauçukta, emaye sırında ve beyaz çimentoda kullanılır.

3. Kaolinin kağıt yapımındaki temel işlevleri

① Kağıdın beyazlığını ve parlaklığını artırın

Kaolinin yüksek beyazlığı, kağıdın beyazlığını etkili bir şekilde iyileştirebilir, onu daha parlak ve daha saf hale getirebilir. Aynı zamanda, ince parçacıkları kağıdın yüzeyinde düzgün bir tabaka oluşturabilir, kağıdın parlaklığını artırabilir ve baskı etkisini iyileştirebilir.

② Kağıdın mukavemetini ve dayanıklılığını artırın

Kağıt yapımı sırasında, kaolin parçacıkları lifler arasındaki boşlukları doldurarak daha sıkı yapılar oluşturabilir, bu da kağıdın çekme mukavemetini, yırtılma mukavemetini ve katlanma direncini iyileştirmeye yardımcı olur. Bu özellikle yüksek kaliteli yazı kağıdı ve baskı kağıdı üretmek için önemlidir.

③ Kağıdın baskıya uyum kabiliyetini artırın

Kaolinin mükemmel yağ emilimi ve dağılabilirliği, mürekkebin kağıt yüzeyine daha eşit yapışmasını sağlar, bu da baskı sırasında baskının geçmesi sorununu bir nebze olsun önleyebilir ve basılı ürünlerin netliğini ve renk doygunluğunu artırabilir.

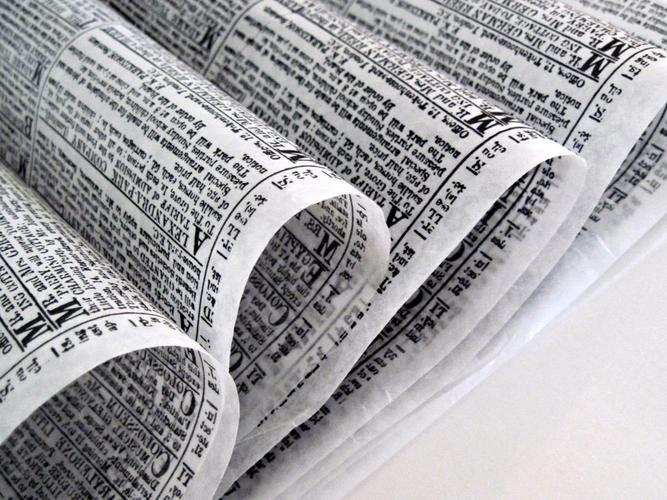

④ Kağıdın mürekkep emilimini ve hava geçirgenliğini ayarlayın

Kaolin miktarının ayarlanmasıyla, kağıdın mürekkep emilim hızı ve hava geçirgenliği hassas bir şekilde kontrol edilebilir, bu sayede farklı tipteki basılı malzemelerin ihtiyaçları karşılanabilir, örneğin: gazete kağıdının hızlı mürekkep emilimi ve kuşe kağıdın yavaş mürekkep emilimi karşılanabilir.

⑤ Üretim maliyetini azaltın

Kaolinin dolgu maddesi olarak kullanılması pahalı odun hamuru kullanımını azaltabilir, bu da üretim maliyetlerini bir miktar düşürebilir.

4. Uygulama beklentisi

Pazar talebinin sürekli büyümesiyle, kaolinin kağıt yapım endüstrisindeki uygulaması artmaya devam edecektir. Ayrıca, işleme teknolojisinin sürekli yenilenmesiyle, ultra ince öğütme ve yüzey modifikasyonu gibi, kaolinin yeni özellikler ve işlevler kazanması kaolinin uygulama alanını ve kapsamını genişletmeye yardımcı olur.

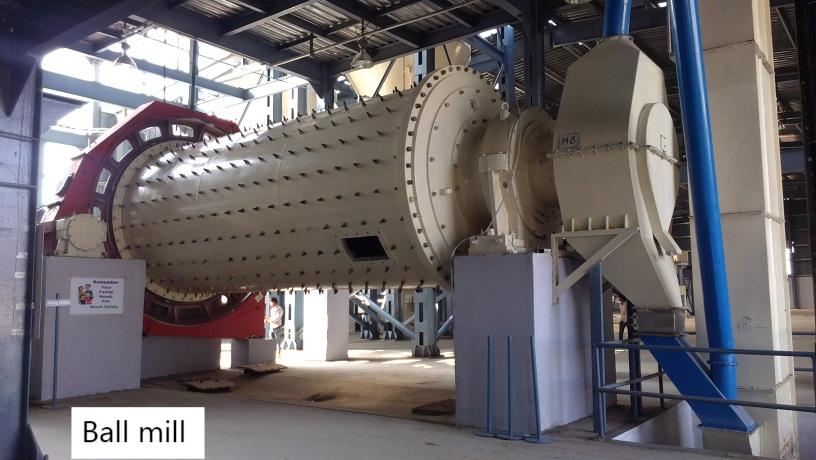

The bilyalı değirmen ve yüzey kaplama değiştiricisi tarafından üretilir Qingdao Destanı Powder Machinery Co., Ltd. sırasıyla kaolinin öğütülmesi ve modifiye edilmesi için uygundur.

Qingdao Epic Toz Makineleri Co., Ltd. toz işleme ekipmanları üretiminde uzmanlaşmış bir üreticidir.

Ürünleri arasında şunlar yer almaktadır:

– Değirmen: bilyalı değirmen, valsli değirmen, jet değirmen, havalı sınıflandırıcı değirmen, titreşimli değirmen ve darbeli değirmen vb.

– Sınıflandırıcı: dört seri hava sınıflandırıcı: HTS, ITC, MBS ve CTC.

– Değiştirici: pim-değirmen değiştiricisi, turbo-değirmen değiştiricisi Ve üç silindirli değirmen değiştiricisi vesaire.

– Yardımcı ekipman: kontrol kabini, toz toplayıcı ve kovalı asansör vb.

– Müşteriler ayrıca ekipmanları kendi ihtiyaçlarına göre özelleştirebilirler, bir müşteri bir tasarım.

İlgili ihtiyaçlarınız veya sorularınız varsa lütfen personel ile iletişim kurun itibaren Qingdao Destanı doğrudan, her zaman hizmetinizdedirler.

Referans olması açısından Qingdao Epic'in bilyalı değirmeni ve yüzey kaplama değiştiricisinin fotoğrafları aşağıdadır.