giriiş

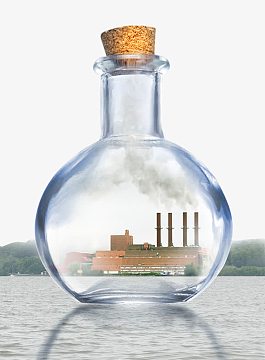

Atık gaz arıtımı yaygın olarak kullanılan bir çevre koruma teknolojisidir, endüstriyel üretim sırasında oluşan atık gazı arıtmak ve kirli havayı emisyon standartlarına uygun hale getirmek için kullanılır. Toz giderme, atık gaz arıtımının önemli bir parçasıdır. Temel ekipmanı siklondur toz toplayıcıSiklon toz toplayıcının tasarımını analiz ederek, farklı çalışma koşullarına uygun formül elde edilebilir ve bu, pratik proje operasyonu için yararlı olacaktır. Siklon toz toplayıcının tasarım faktörleri

① Gaz hızı

Toz sisteminde gazın hareketi esas olarak şu şekilde sağlanır: hız hava akışı. Gaz hızı silindirin teğet yönü boyunca kademeli olarak artar ve hava akışı koninin tepesine ulaştığında maksimum değere ulaşır. 10 mm'den büyük boyutlu parçacıklar için gaz hızı 35 m/s'ye ulaşabilir; 10 mm'den küçük boyutlu parçacıklar için gaz hızı yaklaşık 25 m/s'dir. 25 m/s-35 m/s, birçok tasarımcının toz toplayıcıları tasarlarken benimsediği maksimum verimlilik aralığıdır.

② Rüzgar basıncı

Toz sisteminin toplam basıncı esas olarak hava girişinin statik basıncı, egzoz portunun dinamik basıncı ve dirençten oluşur. Direnç, silindirin şekli ve pürüzlülüğü tarafından belirlenir. Belirli bir sıcaklıkta, gazın mutlak basıncı P, hacim akışı q ile ters orantılıdır, yani P1/q1=k1, burada k1 orantılı katsayıdır. Hava girişinin statik basıncı direncin bir kısmını yenebildiğinden, santrifüjlü toz toplayıcının toplam basıncı eksenel akış tipinden daha düşüktür.

③ Aşınma direnci

Siklon toz toplayıcının aşınma direnci, ekipmanın hizmet ömrünü doğrudan etkiler. Genel olarak, parçacıklar ne kadar büyükse, yoğunluk o kadar büyük olur ve malzemenin yüzeyi ne kadar yapışkansa, aşınma direnci de o kadar büyük olur. Bu nedenle, bir siklon toz toplayıcı tasarlanırken, tozun fiziksel özelliklerini ve toz yüklü gazın özelliklerini dikkate almak gerekir.

④ Parçacık boyutu

Parçacık boyutu, parçacık için temel karakteristik parametrelerden biridir. Örneğin havadaki katı parçacıkları ele alırsak, parçacık boyutu, belirli bir parçacık boyutu aralığındaki katı parçacıkların hacminin, o parçacık boyutundaki parçacıkların toplam hacmine oranını ifade eder. Katı parçacıkların boyutu yalnızca adsorbanın özgül yüzey alanını etkilemekle kalmaz, aynı zamanda adsorpsiyon ve katalitik sürecini de etkiler. Bu nedenle, bir siklon toz toplayıcısı tasarlanırken tozun parçacık boyutu dağılımının dikkate alınması gerekir.

Siklon toz toplayıcı için tasarım formülünün özeti

1. Filtrasyon hızı: G = 200 ~ 800L / dak

2. Gaz akış hızı: Q1 = (38 – P1 / K1) × V1

3. Gaz yükü: P2 = (200-600 Pa)

4. Ayırma verimliliği: e = 95% ~ 99%

5. Toz toplama verimliliği: φ = 100% ~ 98%

6. Basınç düşüşü: △p = 0,396 KPa ~ 0,684 KPa

7. İzin verilen basınç kaybı: △p<0.296KPa

Pratik uygulamada, siklon toz toplayıcı genellikle aşağıdakilerle birleştirilir: değirmen veya sınıflandırıcı sırasında oluşan tozu etkili bir şekilde işlemek ve toplamak için bileme veya sınıflandırma. Qingdao Epic Toz Makineleri Co., Ltd. toz işleme ekipmanlarının profesyonel üreticisidir. Qingdao Epic, çeşitli tipte pulverizatörlerin üretiminde zengin deneyime sahiptir. sınıflandırıcılar Ve toz toplayıcılarÜrünlerimiz yurtiçi ve yurtdışı müşteriler tarafından ilgi görmektedir.

İlgili herhangi bir ihtiyacınız veya sorunuz varsa lütfen bizimle iletişime geçin kadro Qingdao Epic'ten her zaman hizmetinizdeyiz.