There are many types of powder surface modifiers on the market with various functions and prices. How to choose the right powder surface modifier?

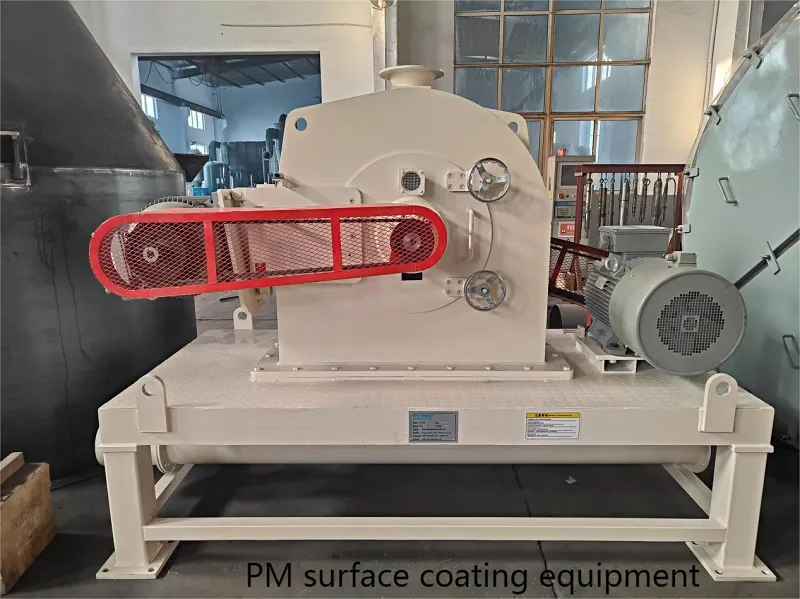

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. Our company has been engaged in this industry for more than ten years, and we have rich production experience and technical accumulation for various mills, surface coating equipment, classifiers and related auxiliary equipment. For surface coating equipment, we have three types: pin-mill modifier, turbo-mill modifier, and three-roter-mill modifier.

Regarding how to choose a suitable powder surface modifier, I will make a simple analysis and summary of this issue based on our company’s many years of practical experience.

Factors affecting surface modifier selection

Practice shows that when selecting a surface modifier, the main considerations include: the properties of the powder raw material, the application of the product, as well as the process and price.

1. Properties of powder raw materials

The properties of powder raw material are mainly acidity, alkalinity, surface structure and functional groups, adsorption and chemical reaction characteristics, etc. When selecting surface modifiers, the ones that can chemically react or chemically adsorb with the surface of powder particles should be selected as much as possible, because physical adsorption is easy to desorb under strong stirring or extrusion during subsequent application.

2. Application of the product

The application of the product is the most important consideration in selecting a surface modifier. Different application fields have different technical requirements for the performance of powders, such as: surface wettability, dispersibility, pH value, hiding power, etc.

3. Modification process

Process factors, such as temperature and environment, also affect the choice of modifiers. For example, organic surface modifier will decompose at a certain temperature, so when selecting this kind of modifier, its decomposition temperature should be higher than the processing temperature during application. While for wet processing, the water solubility of the modifier becomes an important consideration.

4. Price and environmental protection

When selecting a modifier, cost and environmental protection should be considered comprehensively. On the premise of meeting technical indicators, modifiers with low cost, and low environmental pollution should be given priority.

Common types of powder surface modifiers and their applicable scope

— Silane coupling agent

Applicable to inorganic powders, such as: quartz, silicon dioxide, glass fiber, kaolin, etc.

— Titanate coupling agent

Applicable to alkaline minerals, such as calcium carbonate, magnesium carbonate, magnesium oxide, titanium oxide, etc.

–Surfactants

Used to reduce powder agglomeration and improve dispersibility. Commonly used surfactants include anionic surfactants, cationic surfactants and nonionic surfactants.

— Water-soluble polymers

Used to enhance the stability and dispersion of powders in specific applications.

Conclusion

The above are the factors that affect the selection of modifiers based on our company’s practical experience. If you have any needs related to powder modification, I hope the above information will be helpful to you. And if you need surface coating equipment or grinding or classifying equipment, please feel free to contact our staff directly, we are always here for you.