1. Introduction

The powder industry is an important basic raw material industry. Powder manufacturing technology occupies a very important position in chemical industry and material industry. In some polymer material industries and polymer composite materials, inorganic mineral powders are usually used as fillers.

When inorganic mineral powders, such as calcium carbonate, kaolin, mica, quartz, alumina and talc are used as fillers, they need to be surface modified. This is because inorganic mineral materials have different interface properties with organic polymer matrix. So, When used as fillers, besides achieving required particle size and particle size distribution, surface modification of inorganic powder is necessary. This can improve the mechanical properties and comprehensive performance of inorganic powders.

2. Modification methods

Surface physical modification

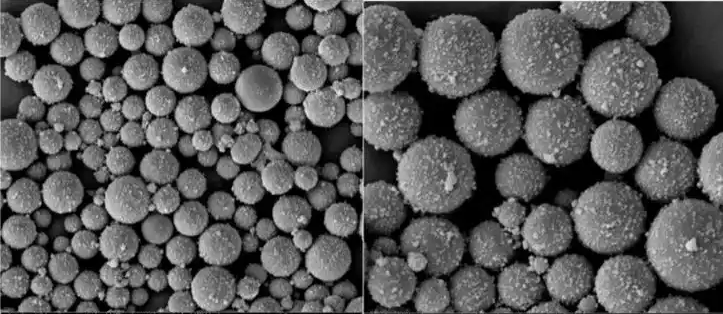

Surface physical modification is to adsorb surface agent onto the surface of inorganic powder particles. It is through intermolecular forces to form a coating layer on the surface of powder particles. This can reduce the surface tension of the powder, and change the surface polarity of particles. At the same time, it can reduce agglomeration between particles.

① Surfactant modification

Surfactant contains hydrophobic groups and hydrophilic groups. It is one of few substances that can significantly change the surface or interface properties of the material. Surfactant has two basic characteristics: (1) It is easy to form directional arrangement on the surface of material or at the interface between two phases, this can improve the surface properties of the material. (2) The solubility of surfactant in the solution is low, and mostly it exists in the state of micelles (assemblies) under the condition of common concentration range, and this can greatly decrease the surface tension of the surfactant.

② High-energy surface modification

The method of surface treatment of inorganic powders by ultraviolet rays, infrared rays and corona discharge is called high-energy surface modification. It is an advanced technology that irradiates or injects these high-density energy sources into the surface of the material. It can cause surface changes on organization and structure of the material, thereby changing the physical, chemical and mechanical properties of the material. These changes can correspondingly change the physical, chemical and mechanical properties of the material.

③ Encapsulation modification

Encapsulation modification is first used in modern medicine field. It was originally developed to meet the demand for sustained release of drug efficacy. Encapsulation modification is to cover the surface of powder particles with a uniform and certain thickness of film. Through the encapsulation modification of microparticles, not only can inorganic/organic composite colloids be prepared and the properties of particles can be changed, but also the sustained release effect of capsules can be achieved, broadening the application range of inorganic powders.

Surface chemical modification

⑴ Surface deposition method

The surface deposition method refers to precipitation reaction of inorganic compounds on the surface of particles, to form one or more layers of “coating” or “encapsulation”. This method can improve the surface properties of powders. This method has three advantages. First, the procedure and equipment are simple, so it is conducive to realize industrialization of production. Second, it can achieve uniform mixing of different components at molecular/atomic level, to accurately control the content of each component. Third, factors of purity, phase composition and particle size etc can be achieved by controlling precipitation condition and calcination degree of powders.

⑵ Chemical coating

Chemical coating is a method of modifying the surface of inorganic powders by partially coating the surface of particles. This method can make the surface of particles organic. There are many types of modification agent used in chemical coating, such as coupling agent and surfactant.

⑶ Mechanically chemical modification

Mechanically chemical modification has two meanings: (1) utilize mechanical stress during ultra-fine grinding to activate mineral surface, this can change surface crystal structure and physical and chemical properties of powders, thereby satisfying application requirement. (2) Utilizing surface activation effect of mechanical stress and the resulting ions or free radicals to initiate polymerization of monomer olefin organic substance, or to enable efficient attachment of modification agent, thereby achieving modification.

3. Summary and Outlook

Surface modification of inorganic powders has become one of the main directions of the development of powder materials today. It is also an important link in the transition of powder materials from stage of scientific research to stage of industrial application. It is generally believed that finer particle size, more active surface and more complex structure are three major directions of development of inorganic fillers in future. So, compounding, ultra-fine grinding and surface modification in the same system will become the main development trend of inorganic powder processing in future.

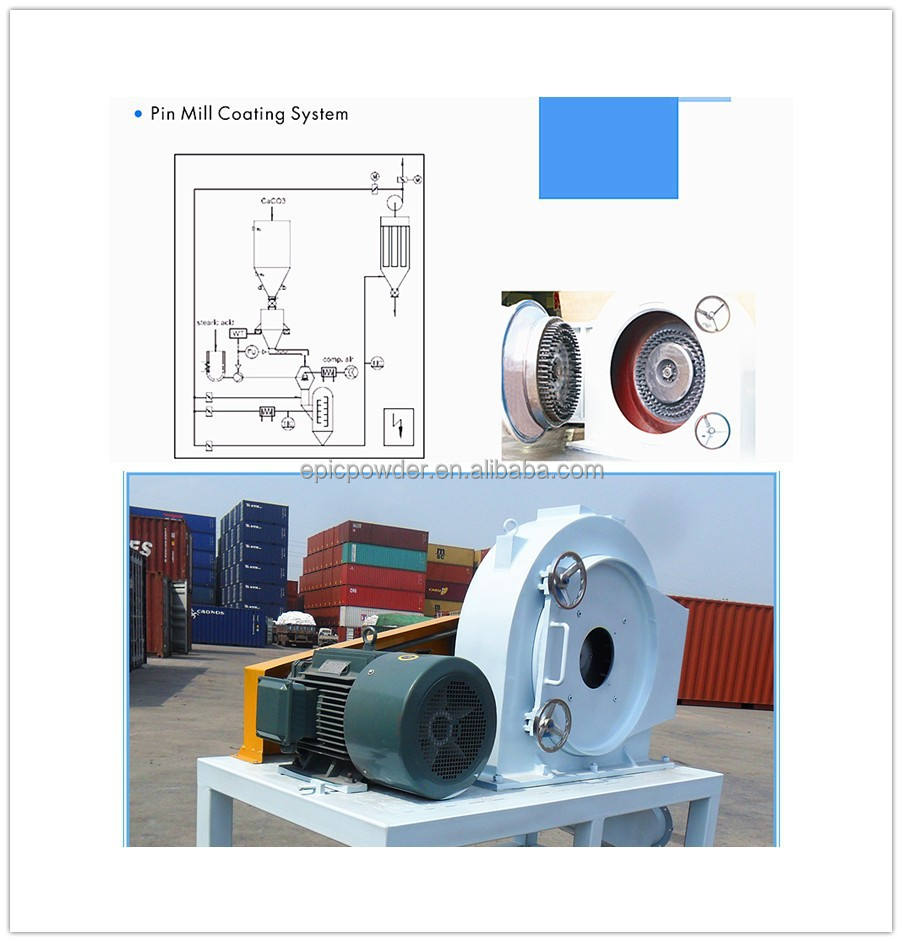

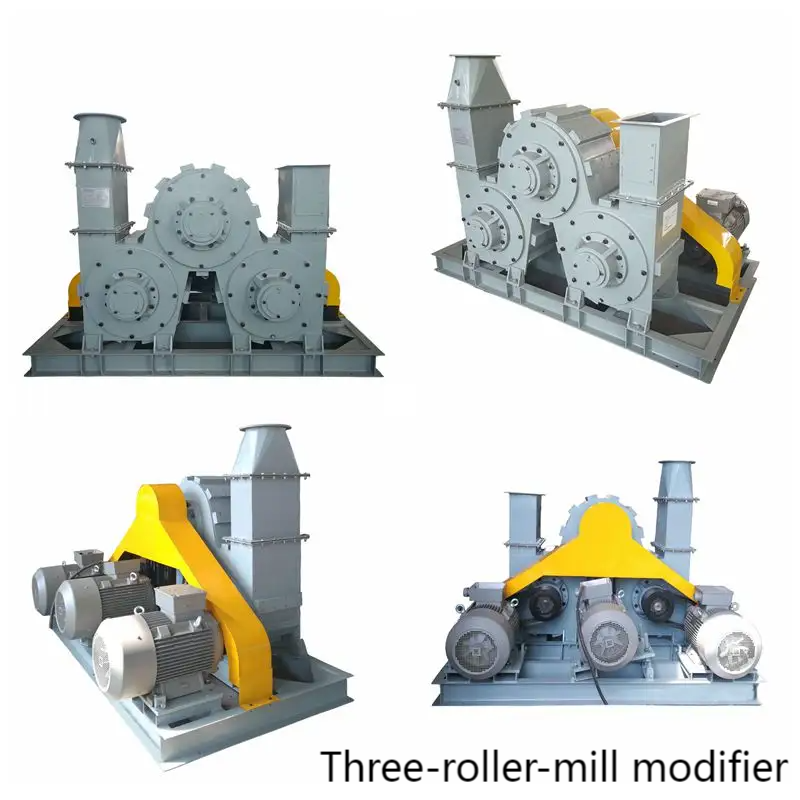

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. Its products include: grinding equipment, classifying/grading equipment, modifying equipment and some auxiliary equipment. Among them, the surface coating modification equipment includes: pin- mill modifier, turbo-mill modifier and three-roller-mill modifier, high efficiency and low energy consumption, especially pin-mill modifier, it is called universal modifier,and has high reputation among customers.

– Mill: ball mill, roller mill, jet mill, air classifier mill, vibration mill and impact mill etc.

– Classifier: four series of air classifiers: HTS, ITC, MBS and CTC.

– Modifier: pin-mill modifier, turbo-mill modifier and three-roller modifier etc.

– Auxiliary equipment: control cabinet, dust collector and suction fan etc.

– Customers can also customize equipment according to their needs, one customer one design.

If you are interested in surface modifier or other equipment from Qingdao Epic , pleas contact their staff directly. They are always at your service.

Below are photos of products from Qingdao Epic for your reference.