1. Введение

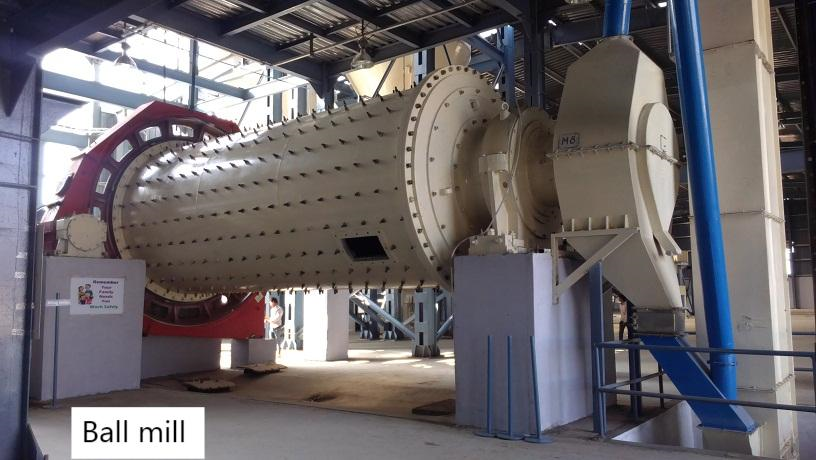

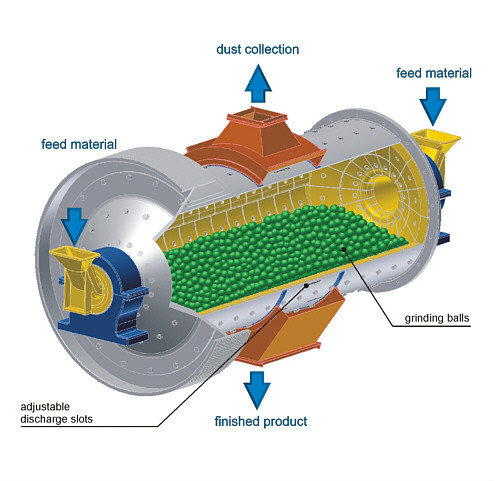

Шаровая мельница — это один из видов оборудования для измельчения порошков, который является ключевым мельница для тонкого помола после грубого дробления. Широко используется в области неметаллических минералов, строительных материалов и химикатов и т. д. Выбор подходящей шаровой мельницы играет важную роль в повышении эффективности производства предприятий по переработке порошков. Ниже приведены некоторые конкретные предложения по выбору шаровой мельницы:

2. Предложения

① Производственная мощность должна быть гарантирована

Сначала необходимо определить необходимую производительность, то есть количество материала, которое необходимо переработать за час или за день, а затем выбрать шаровую мельницу с подходящими характеристиками и моделью.

② Качество и надежность

Очень важно выбрать качественную и надежную шаровую мельницу.

Перед выбором шаровой мельницы лучше посетить место, чтобы протестировать производительность и эффект шаровой мельницы. Это поможет вам лучше понять качество оборудования.

③ Цена

Цена шаровой мельницы варьируется в зависимости от таких факторов, как модель, марка и производительность. Чем выше цена, тем лучше качество. Однако следует отметить, что при выборе шаровой мельницы, помимо цены, следует учитывать комплексную производительность. Следует выбирать шаровую мельницу с высокой производительностью затрат, чтобы достичь экономических и практических целей.

④ Свойства материалов

Разные материалы имеют разные свойства твердости, влажность и размер частиц и т.д. Для этого необходимо выбрать шаровую мельницу, которая должна подходить для обработки целевого материала.

⑤ Безопасность и защита окружающей среды

Шаровая мельница, как крупногабаритное промышленное оборудование, должна соответствовать нормам безопасности и требованиям охраны окружающей среды. Она должна быть оснащена защитными и предохранительными устройствами. При этом потребление энергии и выбросы отходов должны соответствовать экологическим нормам.

⑥ Послепродажное обслуживание поставщика

Поставщики должны предоставлять соответствующие послепродажные услуги и поддержку. Послепродажные услуги включают установку и ввод в эксплуатацию оборудования, ремонт и техническое обслуживание, поставку запасных частей и т. д. Хорошее послепродажное обслуживание требует от поставщиков оперативного реагирования при возникновении проблем и обеспечения стабильной работы оборудования.

3. Резюме

Выбор хорошей шаровой мельницы очень важен для производителей оборудования для переработки порошков. При выборе шаровой мельницы вышеуказанные факторы можно рассматривать как ориентир. Циндао Эпик Порох Машинери Ко., Лтд.. это производитель специализируется на производстве оборудования для переработки порошков. Шаровая мельница является одним из видов их продукции, обладающим хорошей производительностью и низким потреблением энергии, а также хорошим послепродажным обслуживанием.

Продукция Qingdao Epic включает в себя:

– Мельница: шаровая мельница, струйная мельница, мельница с воздушным классификатором (ACM), валковая мельница, вибрационная мельница и ударная мельница и т. д.

– Классификатор: четыре серии воздушных классификаторов: ХТС, МТК, МБС и СТС.

– Модификатор: модификатор штифтовой мельницы, турбомельничный модификатор и трехроликовый модификатор и т.д.

– Вспомогательное оборудование: шкаф управления, пылеуловитель, ковшовый элеватор и ленточный конвейери т. д.

– Клиенты также могут изготавливать оборудование по индивидуальному заказу в соответствии со своими потребностями: один клиент — один дизайн.

Если вас интересует мельница-классификатор или другая продукция от Циндао Эпик, пожалуйста свяжитесь с их персоналом напрямую, они всегда к вашим услугам.

Ниже представлены фотографии с Циндао Эпик для справки.