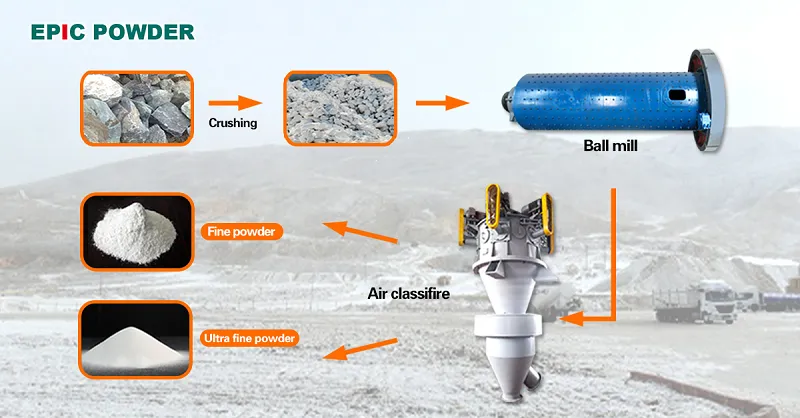

Basalt is a mafic volcanic rock formed by rapid cooling of magma. It has characteristics of high strength, wear resistance, and corrosion resistance, and it plays a significant role in various industries. The powder processing of basalt can adopt ball mill + classifier model, known as ball mill +classifier production line. The advantages of this production line mainly lie in its adaptability, particle size control, energy consumption optimization, and process flexibility. Here is a detailed analysis:

1. Strong adaptability, covering multiple granularity requirements

Raw material compatibility

Ball mill has strong adaptability to basalt hardness (Mohs hardness 5-7) and humidity (≤15%), and it can process block and granular raw materials, especially suitable for large-scale coarse/medium grinding.

Wide particle size range

Ball mill can grind basalt into fine powders of 50-300μm. Combined with air classifier, it can precisely separate products of various specifications, including construction aggregates (20-70mm), manufactured sand (0-5mm), and environmental fillers (<100μm).

2. Collaboration between grinding and classifying to improve efficiency

Real-time particle size control

Air classifier can separate qualified fine powders in time to avoid powder over-grinding in ball mill. This can reduce energy consumption and increase production capacity.

Closed-loop circulation optimization

The coarse particles after classification are returned to milling chamber for further grinding, forming a closed-loop circulation to ensure the uniformity of particle size of finished product.

3. Balance between energy consumption and cost

Suitable for large-scale production

Ball mill has a simple structure and low maintenance cost. It is suitable for large-scale production with an annual output of tens of thousands of tons. The unit energy consumption (about 15-30kWh/t) is lower than that of jet mill (50-100kWh/t).

Energy-saving design of classifiers

Air classifier controls particle size by adjusting airflow velocity and impeller speed, offering higher efficiency than traditional screening equipment, particularly in the separation of ultra-fine powders (<100μm).

4. Stable quality of finished products

Low pollution characteristics

The lining and grinding media can be made of wear-resistant materials (such as: high manganese steel or ceramics) to reduce metal pollution. It is especially suitable for applications with high purity requirements (such as soil conditioners).

Controllable morphology

By adjusting grinding time and grading parameters, angular basalt particles (enhancing bite force in concrete aggregates) or spherical particles (improving flowability for 3D printing powders) can be produced.

5. Environmental protection and safety

Closed system design

Ball mill and classifier are linked by fully enclosed pipelines to minimize dust emission and meet environmental protection requirements.

Inert Gas Protection

During processing of high-reactivity basalt (e.g., oxidizable components), nitrogen gas can be introduced to prevent oxidation and ensure product stability.

Examples of typical production line configurations

Construction Aggregate Line: Jaw crusher → Cone crusher → Vibrating screen (Coarse classification) → Ball mill → Air classifier (Fine powder separation).

Fiber precursor line: Ball mill pre-grinding → Jet mill ultra-fine grinding → Classifier screening → High temperature melt spinning, to ensure uniform fiber diameter.

Qingdao Epic Powder Machinery Co., Ltd. ပရော်ဖက်ရှင်နယ်တစ်ဦးဖြစ်သည်။ ထုတ်လုပ်သူ specializing in powder processing equipment, with years of production experience and technical accumulation. Our products include: powder grinding equipment, classifying equipment, modification equipment, and related auxiliary equipment. Ball mill and classifier are two of our core products. Our Ball Mill + အမျိုးအစားခွဲသည်။ Production Line is an internationally advanced solution for grinding and classifying non-metallic mineral powders, including basalt. It is with high efficiency, low energy consumption, and has earned positive feedback from customers.

If you need to grind and grade non-metallic mineral powders or other materials, please contact Epic Powder, and we will provide you with a one-stop solution from equipment selection, solution design to installation and commissioning, and after-sales service.

Contact us! Our professional equipment will assist you in achieving more efficient and intelligent powder processing!