Reasons for calcium carbonate modification

Calcium carbonate is one type of filling materials with multiple functions. It has characteristics of affordable price, high stability, pure color and non-toxicity, and it is widely used in fields of plastics, rubber, paper-making, building materials and wires and cables etc. However, the surface of calcium carbonate powder is hydrophilic and oleophobic, with strong polarity. This makes it difficult for calcium carbonate to disperse evenly in organic media, and weak to bond with substrate, so it is easily impacted by external forces, resulting in interface defects and decreased material performance.

The problem of nano calcium carbonate powder lies in its high surface energy. The high surface energy can enhance adsorption, causing particles difficult to disperse evenly in polymer matrix, so it would affect application performance.

The effect of calcium carbonate modification

Modification of calcium carbonate powder can both increase repulsion and reduce attraction between particles, thereby improving its dispersibility. In addition, modification can also increase surface activity of particles and enhance its compatibility, meanwhile, it endows calcium new properties in physical, chemical and mechanical aspects, as well as new functions. This can not only improve the performance of products, but also further broaden the application field of calcium carbonate.

Classification of calcium carbonate modification

In recent years, modification of calcium carbonate has become a hot topic at home and abroad. According to modification principle, the modification methods can be divided into physical modification and chemical modification.

Physical modification

Physical modification refers to surface coating or adsorption. It doesn’t involve chemical reaction between powder and modification agent, while it relies on van der Waals force and hydrogen bonding. And agglomeration is achieved through the attraction of electric charge.

Chemical modification

Chemical modification also includes mechanical force and surface chemical modification. During pulverization process, chemical modification utilizes mechanical stress to activate particle surface, and then to adjust its surface crystal and physical and chemical structure to realize surface modification. While surface chemical modification utilizes surface activity of organic functional groups, to chemically react with surface atoms of particles, so that the surfactant can cover the surface of particles. This makes calcium carbonate change from inorganic hydrophilic to organic lipophilic, optimizing properties of the product.

Summary

Modifying calcium, as an industry with high added value, has achieved remarkable results in many fields. Its vigorous development can not only endow abundant inorganic non-metallic mineral resources with economic advantages, but also improve the quality and competitiveness of products in related industries. When developing functional calcium fillers, we should focus on its economic efficiency, and deeply explore its properties of functionality and environmental protection in finished products. In future development, we should turning from pursuit of profit to a new realm of sustainable development.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment.

Its products include: grinding equipment, classifying/grading equipment, modifying equipment and some auxiliary equipment.

– Mill: air classifier mill(ACM), ball mill, ကြိတ်စက်, jet mill, vibration mill and impact mill etc.

– Classifier: four series of air classifiers: HTS , ITC, MBS and CTC.

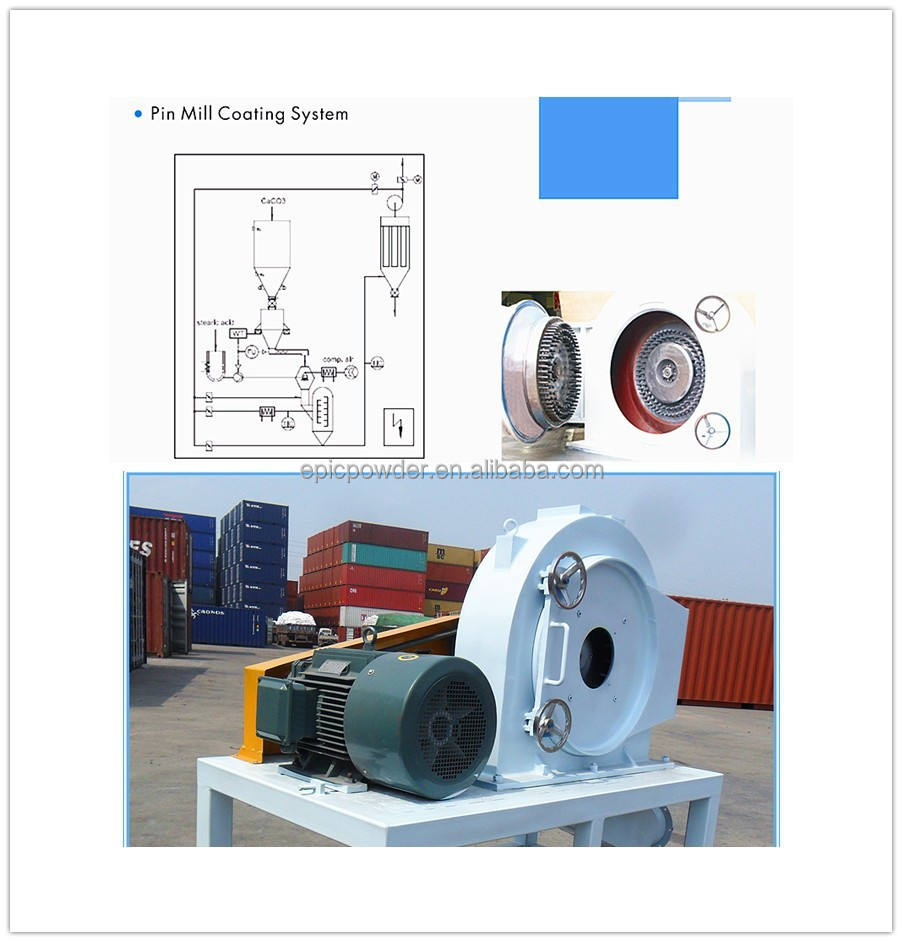

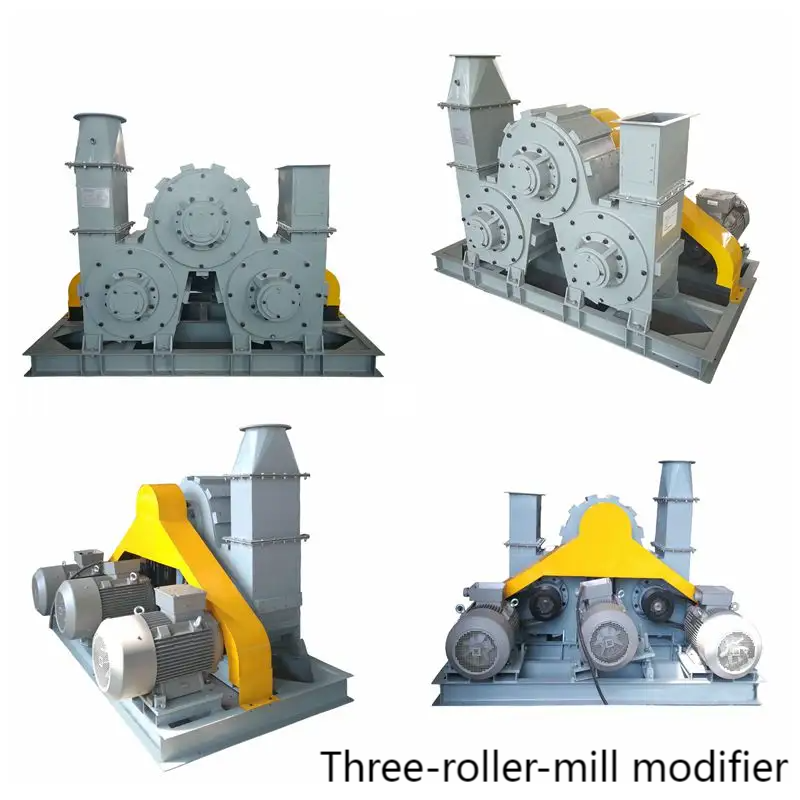

– Modifier: pin-mill modifier, turbo-mill modifier and three-roller modifier etc.

– Auxiliary equipment: control cabinet, dust collector and sunction fan etc.

– Customers can also customize equipment according to their needs, one customer one design.

Among them, surface modifier for calcium powder and other powders includes: pin-mill modifier, turbo-mill modifier and three-roller-mill modifier, especially pin-mill modifier, is called universal modifier, and has high reputation among customers.

If you are interested in surface modifier or other equipment from Qingdao Epic , pleas contact their staff directly. They are always at your service.

Below are photos from Qingdao Epic for your reference.