Introduction

Activated carbon is a specially treated carbon. Through heating organic raw material (coal and wood, etc) in an air-tight environment can reduce non-carbon components. This process is called carbonization. And then react heated organic raw material with gas to produce product with a well-developed microporous structure. This process is called activation.

In recent years, activated carbon has received widespread attention in powder processing industry. Through grinding, the surface energy and specific surface area of particles increase, and more pore structures and surface active sites are generated, this can enhance the adsorption performance of activated carbon, which enables it to play a better role in water purification, sewage treatment, air purification, car deodorization, etc.

Powder processing of activated carbon

First step: crushing

Use a crusher to grind raw activated carbon into qualified particle sizes that meet the feeding requirement.

Second step: purification

Select high- quality activated carbon particles as raw material, and then remove impurities through screening and washing to ensure the purity of raw material.

Third step: grinding

Put purified activated carbon particles in a mill, and grind them into fine powders by mechanical force. This process can increase the surface energy and specific surface area of activated carbon particles, thereby improving their adsorption performance.

Forth step: classification

The ground activated carbon powders are separated by a classifier. This process can obtain powders with required fineness, and then ensure the consistency of product specifications.

Fifth step: packaging and storage

Finally, the processed activated carbon powders are packaged and stored for future use.

Conclusion

Through above steps, we can obtain activated carbon powders that meet specific particle size requirements, this is helpful for activated carbon powders to play a better role in more fields.

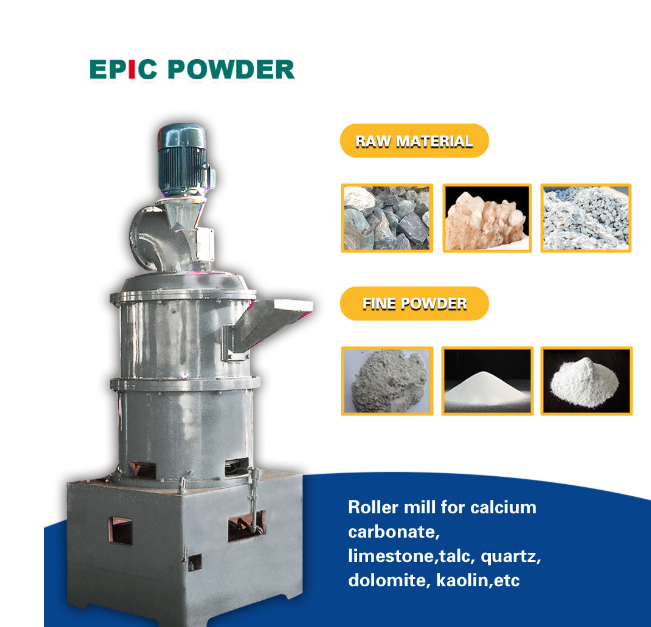

Roller mill produced by Qingdao Epic Powder Machinery Co., Ltd is very suitable for grinding activated carbon, with high efficiency and low energy consumption.

Qingdao Epic Powder Machinery Co., Ltd is a manufacturer specializing in the production of powder machinery.

Our main products include:

– Mills: pabrik rol, ball mill, air classifier mill(ACM), jet mill and turbo mill etc.

– Air Classifiers: include four series: HTS, ITC, MBS and CTC .

– Surface coating modifiers: pin-mill modifier, turbo-mill modifier and three-rotor-mill modifier, etc.

– Auxiliary equipment: control cabinet, dust collector and suction fan, etc.

– Customers can customize products according to actual needs. One customer, one design.

If you have relevant demands for roller mill or other products from Qingdao Epic, contact our staff directly, we are always at your service.

Below are roller mill from Qingdao Epic for your reference.