1. Introduction

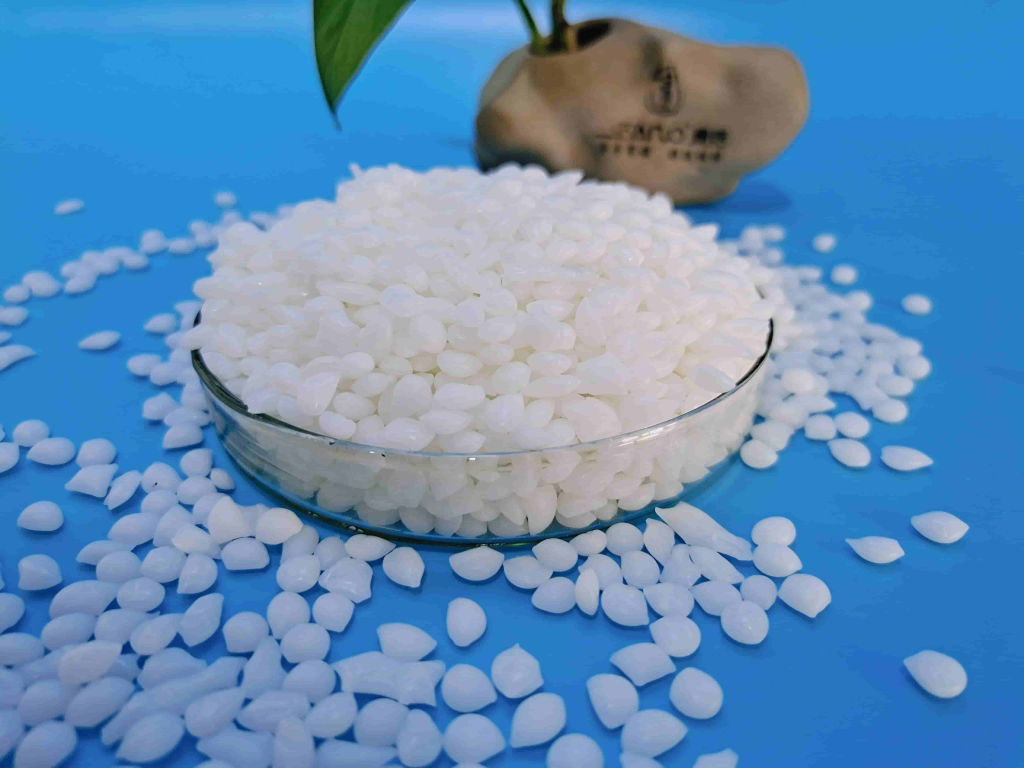

Polyethylene wax (PE wax) is a chemical material, it is white in color and in the form of small micro beads or flakes. It has characteristics of high melting point, high hardness and high glossiness.

2. The effect of PE wax in coatings

Applying polyethylene wax (PE wax) to coatings has many good effects. Below are some of the key effects:

● Improve scratch resistance

PE wax can form a protective layer on coating surface, which greatly reduces the possibility of scratches and wear. This is essential to maintain visual and functional integrity of coatings.

● Enhance surface finish

PE wax can modify the glossiness of coatings, allowing the product to achieve desired aesthetic effects, no matter shiny or matte.

● Enhance anti-adhesion performance

When used in coatings, PE wax can gradually migrate to the surface of the film, forming a protective film to prevent the adhesion between film surface and external substance. This migration effect makes the paint film less likely to be stained by dust, dirt, or pressure when exposed to the atmosphere.

● Increase smoothness of coatings

The addition of PE wax improves the smoothness of coating, making it smoother and easier to handle during applications, such as printing or spraying.

● Enhance water resistance

PE wax can enhance water resistance of the coating, it can provide a moisture barrier to prevent the coating from degrading or becoming damaged over time.

● Enhance thermal stability

PE wax has excellent thermal stability in coatings. Under high temperature conditions, PE wax can maintain stable chemical and physical properties, and it is not prone to decomposition or deterioration. PE wax performs well in coatings and can slow down and prevent aging of coatings.

● Enhance chemical resistance

The coating with PE wax has better tolerance to various chemicals. PE wax has excellent chemical resistance in coatings and can effectively resist the erosion of various chemicals, thereby extending the service life of coatings.

3. Summary

The application prospect of PE wax in coatings is very broad. With the continuous development of coating technology, the demand for high-performance, environmentally friendly coatings is increasing. As an environmentally friendly additive, PE wax would have great development potential in future coating market.

In practice, PE wax can be crushed and classified by pulverizer and classifier. The jet mill and air classifier produced by Qingdao Epic Powder Machinery Co., Ltd. are suitable for grinding and classifying PE wax, with good performance.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment.

Its products include:

– Mill: jet mill, ball mill, mill, pabrik rol, air classifier mill(ACM), vibration mill and impact mill etc.

– Penggolong: four series of air classifiers: HTS, ITC, MBS and CTC.

– Modifier: pin-mill modifier, turbo-mill modifier and three-roller modifier etc.

– Auxiliary equipment: control cabinet, dust collector and bucket elevator etc.

– Customers can also customize equipment according to their needs, one customer one design.

If you are interested in jet mill and air classifier or other products from Qingdao Epic, please contact staff directly, they are always at your service.

Below are photos from Qingdao Epic for your reference.