1 परिचय

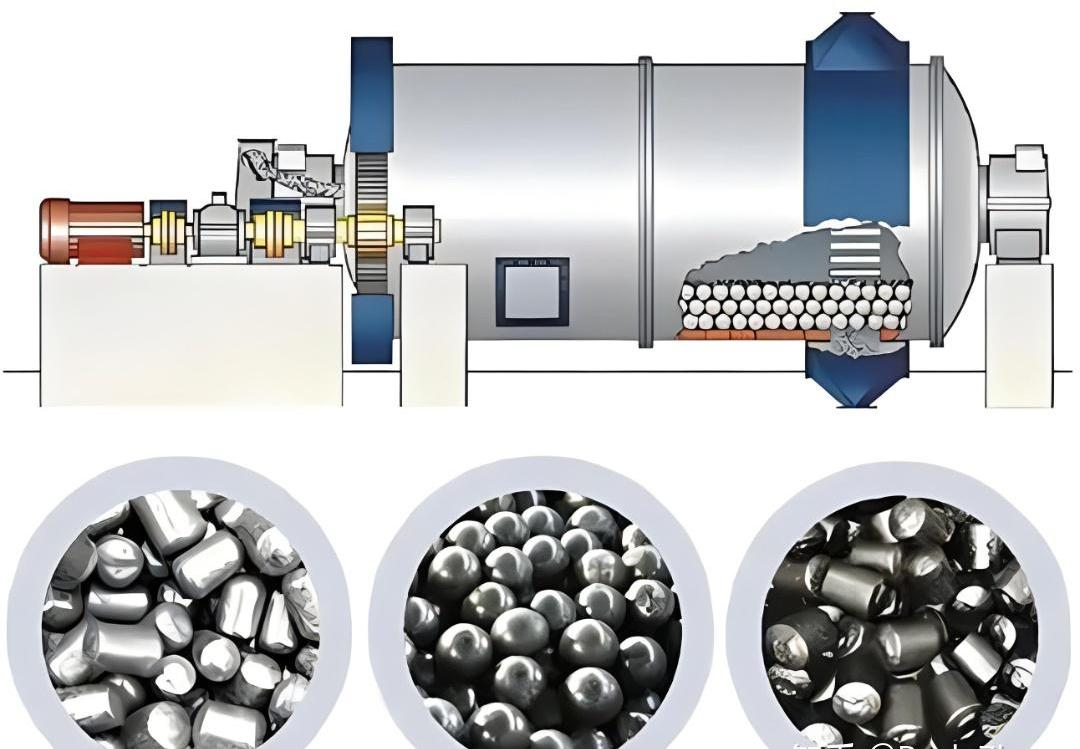

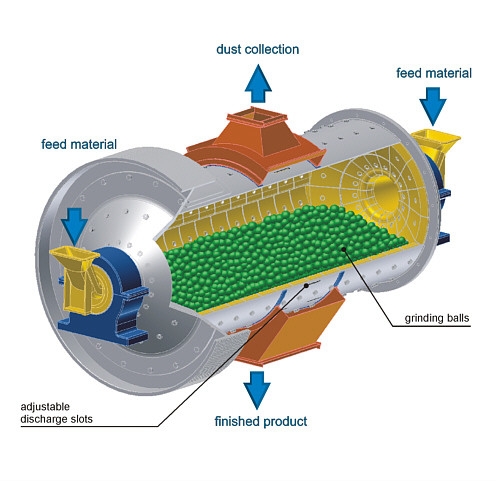

बॉल मिल एक प्रकार की मुख्य मशीनरी है जो सामग्री को कुचलने के बाद पीसने के लिए उपयोग की जाती है। बॉल मिल विभिन्न पीसने के लिए उपयुक्त है अयस्कों और अन्य सामग्री। पीसने की प्रक्रिया को अनुकूलित करने और पीसने की दक्षता में सुधार करने के लिए, उपयुक्त बॉल आकार का चयन करना आवश्यक है। निम्नलिखित मुख्य कारक हैं:

2. गेंद का आकार चुनने के लिए विचार

2.1. सामग्री की कठोरता

सामग्री की कठोरता सीधे गेंद के आकार के चयन को प्रभावित करती है। कठोर सामग्री के लिए आमतौर पर बड़ी गेंदों की आवश्यकता होती है, ताकि प्रभावी पीसने के लिए अधिक प्रभाव ऊर्जा उत्पन्न हो सके, जबकि नरम सामग्री के लिए आमतौर पर छोटी गेंदों की आवश्यकता होती है।

2.2. सामग्री का आकार

जब सामग्री का आकार बड़ा हो, तो सामग्री को पीसने के लिए पर्याप्त प्रभाव बल प्रदान करने के लिए, बड़ी गेंदों का चयन किया जाना चाहिए। इसके विपरीत, यदि सामग्री का आकार छोटा है, तो पीसने की दक्षता और पाउडर की सुंदरता को और बेहतर बनाने के लिए, छोटी गेंदों का चयन किया जाना चाहिए।

2.3. मिल का प्रकार

विभिन्न प्रकार की मिलों को अलग-अलग बॉल साइज़ की आवश्यकता होती है। औद्योगिक मिलों में बड़ी बॉल (100 मिमी या उससे बड़ी) को समायोजित किया जा सकता है, जो बड़ी मात्रा में सामग्री को संसाधित करने के लिए आवश्यक हैं।

2.4. बॉल मिल का व्यास और गति

बॉल मिल का व्यास और गति भी बॉल के आकार को प्रभावित करेगी। बड़ी बॉल मिलों को आमतौर पर बड़ी गेंदों की आवश्यकता होती है, जबकि छोटी गेंदें अधिक गति होने पर अधिक उपयुक्त होती हैं, क्योंकि छोटी गेंदें उच्च गति वाले रोटेशन के दौरान सामग्री को बेहतर ढंग से फैला सकती हैं और पीस सकती हैं।

3. निष्कर्ष

जैसा कि ऊपर उल्लेख किया गया है, गेंद के आकार को प्रभावित करने वाले कई कारक हैं। वास्तविक संचालन में, वास्तविक स्थिति के आधार पर विभिन्न कारकों पर व्यापक रूप से विचार करना और उत्पादन दक्षता में सुधार के लिए उपयुक्त गेंदों का चयन करना आवश्यक है।

क़िंगदाओ महाकाव्य पाउडर मशीनरी कं, लिमिटेड पाउडर मशीनरी के उत्पादन में विशेषज्ञता वाला एक निर्माता है।

हमारे मुख्य उत्पादों में शामिल हैं:

–मिल्स: बॉल मिल, रोलर मिल, एयर क्लासिफायर मिल (एसीएम), टर्बो मिल और इम्पैक्ट मिल, आदि।

–वर्गीकरणकर्तावायु वर्गीकरणकर्ताओं की चार श्रृंखलाएँ: एचटीएस, आईटीसी, एमबीएस, सीटीसी.

–संशोधक: पिन-मिल संशोधक, टर्बो-मिल संशोधक और तीन-रोलर-मिल संशोधक, आदि।

–सहायक उपकरण: नियंत्रण कैबिनेट, धूल संग्रहित करने वाला और बाल्टी लिफ्ट, आदि.

-ग्राहक वास्तविक जरूरतों के अनुसार उत्पादों को अनुकूलित कर सकते हैं। एक ग्राहक, एक डिज़ाइन.

यदि आपके पास बॉल मिल या अन्य उत्पादों के लिए प्रासंगिक ज़रूरतें या प्रश्न हैं, तो कृपया बेझिझक संपर्क करें क़िंगदाओ महाकाव्य, हमारा स्टाफ़ आपकी सेवा के लिए सदैव तत्पर है।

नीचे से तस्वीरें हैं क़िंगदाओ महाकाव्य आपके संदर्भ के लिए।