बॉल मिल का इस्तेमाल विभिन्न उद्योगों में सामग्री को बारीक पाउडर में पीसने के लिए व्यापक रूप से किया जाता है। हालाँकि, कुछ कारणों से, यह संचालन के दौरान अत्यधिक गर्मी उत्पन्न कर सकता है, फिर पीसने की दक्षता और तैयार उत्पादों दोनों को प्रभावित कर सकता है। इसलिए बॉल मिल के गर्म होने के कारणों को समझना इसके प्रदर्शन को अनुकूलित करने और संभावित नुकसान को रोकने के लिए महत्वपूर्ण है। बॉल मिल के गर्म होने के मुख्य कारण नीचे दिए गए हैं:

1. आंतरिक टक्कर

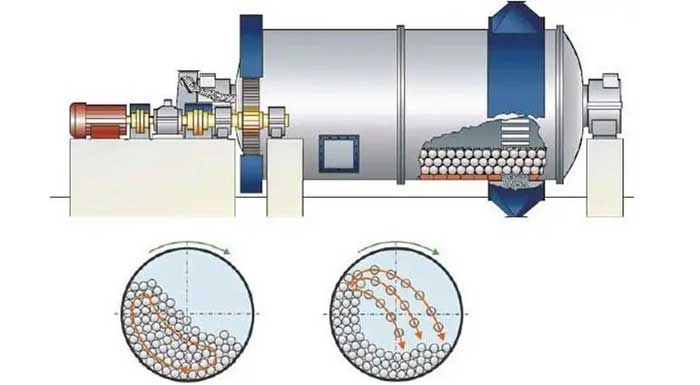

बॉल मिल की पीसने की प्रक्रिया में बॉल-टू-बॉल और बॉल-टू-मटेरियल की टक्कर शामिल होती है। टक्कर के परिणामस्वरूप महत्वपूर्ण आंतरिक घर्षण होता है, जो गर्मी उत्पन्न करता है।

① ऑपरेटिंग आवृत्ति: उच्च ऑपरेटिंग आवृत्ति गेंदों की गतिज ऊर्जा को बढ़ाती है, जिससे अधिक टकराव और अधिक गर्मी पैदा होती है। उदाहरण के लिए, 30 हर्ट्ज की ऑपरेटिंग आवृत्ति पर, तापमान काफी बढ़ सकता है।

② गेंदों की मात्रामिल में सामग्री और गेंदों की मात्रा इस बात को प्रभावित करती है कि कितनी ऊर्जा गर्मी के रूप में नष्ट होती है। अधिक गेंद भरने से अधिक टकराव हो सकता है, फिर अधिक गर्मी उत्पन्न हो सकती है।

2. सामग्री का गुण

✱सामग्री कठोरताकठोर पदार्थ को पीसने के लिए अधिक ऊर्जा की आवश्यकता होती है, जिसके परिणामस्वरूप अधिक टकराव और गर्मी उत्पन्न होती है।

✱नमी की मात्रायदि सामग्री में बहुत अधिक नमी है, तो पीसने की प्रक्रिया के दौरान उत्पन्न गर्मी जल वाष्प के माध्यम से मिल से बाहर नहीं जा सकती है, जिससे अधिक गर्मी पैदा होती है।

3. शीतलन प्रणाली

बॉल मिल में आमतौर पर प्रभावी शीतलन प्रणाली का अभाव होता है, जिससे अधिक गर्मी पैदा होती है। पानी इंजेक्शन सिस्टम या कूलिंग नोजल गर्मी को खत्म करने और तापमान को नियंत्रित करने में मदद कर सकते हैं।

4. जारी करना स्नेहन

गतिशील भागों के बीच घर्षण को कम करने के लिए उचित स्नेहन आवश्यक है।

सहन करना तापमान: अपर्याप्त स्नेहन के कारण बियरिंग अधिक गर्म हो जाएगी और बॉल मिल के अंदर अधिक गर्मी पैदा होगी।

5. यांत्रिक मिसलिग्न्मेंट

घटकों के बीच गलत संरेखण असमान घिसाव और बढ़े हुए घर्षण का कारण बन सकता है, जिससे संचालन के दौरान उच्च तापमान हो सकता है। इसके अलावा, बड़ी मिलों के कारण समय के साथ नींव बैठ सकती है, जिससे गलत संरेखण होता है जिससे परिचालन तनाव और अधिक गर्मी बढ़ जाती है।

6. सामग्री का अतिभार

बॉल मिल के संचालन के दौरान, यदि सामग्री को अधिक भार दिया जाता है, तो संचालन के लिए आवश्यक ऊर्जा तदनुसार बढ़ जाएगी, और मिल घटकों के घर्षण से उत्पन्न आणविक आंदोलन अधिक लगातार और तीव्र हो जाएगा, जिसके परिणामस्वरूप तापमान में वृद्धि होगी। इसके अलावा, बड़े कणों वाली सामग्री अधिक घर्षण उत्पन्न करेगी, जिससे अधिक गर्मी पैदा होगी।

निष्कर्ष

बॉल मिल संचालन के दौरान गर्मी को नियंत्रित करना उपकरण के सामान्य संचालन को सुनिश्चित करने और इसकी सेवा जीवन को बढ़ाने के लिए आवश्यक है। संचालन के दौरान गर्मी उत्पादन के कारणों को समझने से वास्तविक अनुप्रयोग में ओवरहीटिंग से बचने में मदद मिल सकती है।

क़िंगदाओ एपिक पाउडर मशीनरी कं, लिमिटेडपाउडर प्रसंस्करण उपकरण के उत्पादन में विशेषज्ञता वाला एक निर्माता है।

इसके उत्पादों में शामिल हैं:

– मिल: बॉल मिल, रोलर मिल, जेट मिल, एयर क्लासिफायर मिल, कंपन मिल और प्रभाव मिल आदि।

– वर्गीकृत करेंवायु वर्गीकरणकर्ताओं की चार श्रृंखलाएं: एचटीएस, आईटीसी, एमबीएस और सीटीसी।

– संशोधकपिन-मिल संशोधक, टर्बो-मिल संशोधक और तीन-रोलर संशोधक आदि।

– सहायक उपकरण: नियंत्रण कैबिनेट, धूल कलेक्टर और बाल्टी लिफ्ट आदि।

- ग्राहक अपनी आवश्यकताओं के अनुसार भी अनुकूलित कर सकते हैं, एक ग्राहक एक डिजाइन.

यदि आपकी कोई प्रासंगिक आवश्यकताएँ या प्रश्न हों, तो कृपया संपर्क स्टाफ से क़िंगदाओ महाकाव्य सीधे तौर पर, वे सदैव आपकी सेवा में हैं।

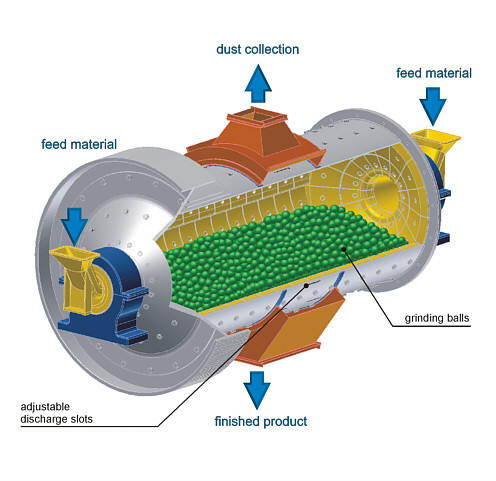

नीचे आपके संदर्भ के लिए क़िंगदाओ महाकाव्य से गेंद मिल की तस्वीरें हैं।