400 मेश के भारी कैल्शियम कार्बोनेट पाउडर की कीमत अलग-अलग क्षेत्रों, अलग-अलग उत्पादन लागत और अलग-अलग सफेदी के आधार पर अलग-अलग होती है। 400 मेश वाले भारी कैल्शियम का इस्तेमाल आमतौर पर भराव के रूप में किया जाता है, और इसका इस्तेमाल रबर, प्लास्टिक, कागज बनाने के उद्योगों में व्यापक रूप से किया जाता है। कोटिंग्स, निर्माण सामग्री, भोजन, दवा और चारा।

विभिन्न उद्योगों में भारी कैल्शियम का अनुप्रयोग:

1. कोयला आधारित बिजली संयंत्र उद्योग

कोयला आधारित बिजली संयंत्र उद्योग में कैल्शियम कार्बोनेट का मुख्य उपयोग फ़्लू गैस डिसल्फ़राइज़ेशन है। चूना पत्थर फ़्लू गैस डिसल्फ़राइज़ेशन का अर्थ है कोयले के दहन के दौरान उत्पादित कैल्शियम कार्बोनेट और सल्फर डाइऑक्साइड से कैल्शियम सल्फाइट को संश्लेषित करना, और फिर कैल्शियम सल्फाइट हवा के संपर्क में आने पर जिप्सम में ऑक्सीकरण हो सकता है, जिप्सम सल्फर डाइऑक्साइड के उत्सर्जन को 90% तक प्रभावी रूप से कम कर सकता है। साथ ही, उत्पादित डीसल्फराइज्ड जिप्सम को सीधे सीमेंट प्लांट या जिप्सम बोर्ड प्लांट को उत्पाद के रूप में बेचा जा सकता है।

2. पेंट उद्योग

पेंट में भारी कैल्शियम का उपयोग मुख्य रूप से लागत को कम करने और कठोरता को बढ़ाने के लिए किया जाता है। आम तौर पर, जब इसे मुख्य भराव के रूप में उपयोग किया जाता है, तो कण की सूक्ष्मता लगभग 400 से 325 जाल के आसपास होनी चाहिए, और सफेदी 80% से कम नहीं होनी चाहिए।

3. चारा उद्योग

फ़ीड उद्योग में उपयोग किए जाने वाले भारी कैल्शियम के लिए महीनता 325 जाल, सफेदी 95%, शुद्धता 99%, बिना किसी अशुद्धता की आवश्यकता होती है। कैल्शियम कार्बोनेट फ़ीड में कैल्शियम की मात्रा बढ़ा सकता है और फ़ीड की गुणवत्ता में सुधार कर सकता है।

4. फ़्लोर टाइल उद्योग

फर्श टाइलों के लिए, भारी कैल्शियम की आवश्यकता है: 400 जाल, सफेदी 95%, शुद्धता: 98.5%, अशुद्धियों के बिना। जब फर्श टाइल में उपयोग किया जाता है, तो कैल्शियम कार्बोनेट सफेदी और तन्य शक्ति को बढ़ा सकता है और उत्पाद की कठोरता में सुधार कर सकता है, इस बीच उत्पादन लागत को कम कर सकता है।

5. कागज बनाने का उद्योग

कागज़ बनाने के लिए भारी कैल्शियम कार्बोनेट की आवश्यकता 325 जाल से अधिक की महीनता, सफेदी 95%, शुद्धता 98% होती है। कागज़ बनाने के उद्योग में कैल्शियम कार्बोनेट की महत्वपूर्ण भूमिका होती है। यह कागज़ की मज़बूती और सफेदी सुनिश्चित कर सकता है, और लागत कम कर सकता है।

6. रबर उद्योग

जब रबर में भारी कैल्शियम का उपयोग किया जाता है, तो सूक्ष्मता 400 जाल, सफेदी 93%, शुद्धता 96% तक पहुंचने की आवश्यकता होती है। कैल्शियम कार्बोनेट रबर उद्योग में सबसे अधिक इस्तेमाल किए जाने वाले भरावों में से एक है। यह रबर उत्पादों की मात्रा बढ़ा सकता है और लागत कम करने के लिए प्राकृतिक रबर को बचा सकता है। भराव के रूप में कैल्शियम कार्बोनेट के साथ, रबर शुद्ध रबर वल्केनाइज़ेट की तुलना में अधिक तन्य शक्ति, आंसू शक्ति और पहनने के प्रतिरोध प्राप्त कर सकता है।

7. कृत्रिम संगमरमर उद्योग

कृत्रिम संगमरमर में भरते समय, भारी कैल्शियम की सुंदरता लगभग 325 से 400 जाल, सफेदी 95% और शुद्धता 98.5% होनी चाहिए, बिना किसी अशुद्धता के। वर्तमान में, कृत्रिम संगमरमर के उत्पादन में कैल्शियम कार्बोनेट का व्यापक रूप से उपयोग किया जाता है।

आवेदन संभावना

बाजार की मांग के निरंतर विस्तार के साथ, भारी कैल्शियम के अनुप्रयोग की संभावनाएं व्यापक होंगी। एक शब्द में, भारी कैल्शियम का भविष्य में बहुत बड़ा आर्थिक मूल्य और बाजार क्षमता होगी।

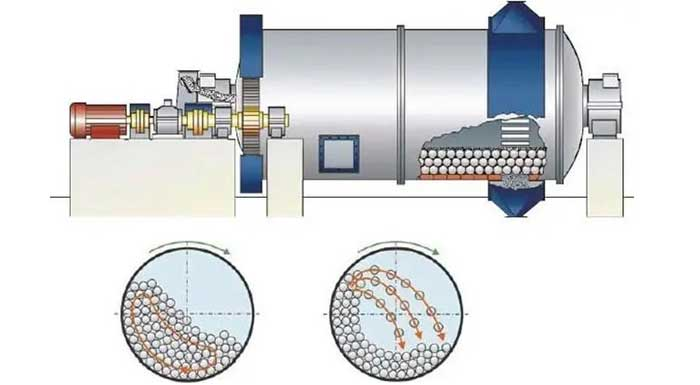

विभिन्न अनुप्रयोग क्षेत्रों में विभिन्न आवश्यकताओं को पूरा करने के लिए, विभिन्न सूक्ष्मता वाले भारी कैल्शियम को वर्गीकृत करना अपरिहार्य है, इसलिए कैल्शियम कार्बोनेट के बेहतर अनुप्रयोग के लिए पीसने और वर्गीकरण उपकरणों का उपयोग अपरिहार्य है, जैसे: बॉल मिल और क्लासिफायर।

क़िंगदाओ एपिक पाउडर मशीनरी कं, लिमिटेड. पाउडर प्रसंस्करण उपकरण के उत्पादन में विशेषज्ञता निर्माता है।

उत्पादों में शामिल हैं:

– मिल: बॉल मिल, रोलर मिल, जेट मिल, एयर क्लासिफायर मिल, कंपन मिल और प्रभाव मिल आदि।

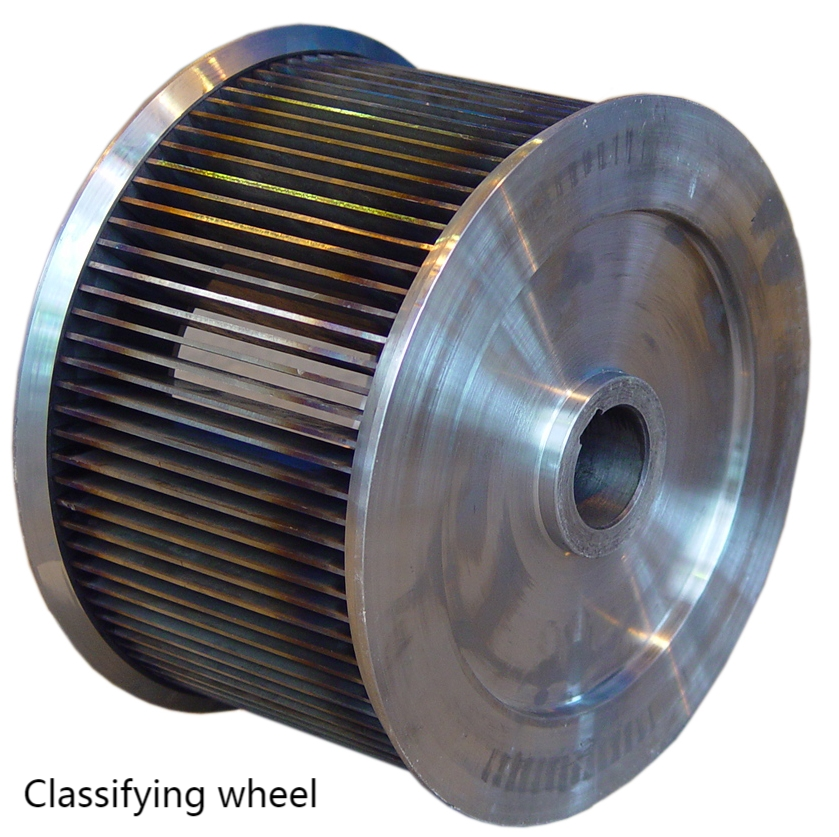

- क्लासिफायर: वायु क्लासिफायर की चार श्रृंखलाएँ: एचटीएस, आईटीसी, एमबीएस और सीटीसी।

– संशोधक: पिन-मिल संशोधक, टर्बो-मिल संशोधक और तीन-रोलर संशोधक आदि।

– सहायक उपकरण: नियंत्रण कैबिनेट, धूल कलेक्टर और बाल्टी लिफ्ट आदि।

- ग्राहक अपनी आवश्यकताओं के अनुसार भी अनुकूलित कर सकते हैं, एक ग्राहक, एक डिजाइन.

यदि आपकी कोई प्रासंगिक आवश्यकताएँ या प्रश्न हों, तो कृपया संपर्क स्टाफ से क़िंगदाओ महाकाव्य सीधे तौर पर, वे सदैव आपकी सेवा में हैं।

आपके संदर्भ के लिए नीचे क़िंगदाओ एपिक की तस्वीरें दी गई हैं।