1. संक्षिप्त परिचय

बैराइट, एक महत्वपूर्ण गैर-धात्विक कच्चा खनिज है, जो मुख्य रूप से बेरियम सल्फेट (BaSO4) से बना है। पानी में अघुलनशील होने, उच्च घनत्व और अच्छी भरने की क्षमता की विशेषताओं के साथ, बैराइट का कई क्षेत्रों में उच्च अनुप्रयोग मूल्य है।

2. विशिष्ट अनुप्रयोग

✱ तेल के लिए भार एजेंट ड्रिलिंग कीचड़

तेल की ड्रिलिंग में बैराइट की अहम भूमिका होती है। ड्रिलिंग मड के मुख्य भारोत्तोलक एजेंट के रूप में, बैराइट मड के घनत्व को काफी हद तक बढ़ा सकता है। यह ड्रिल बिट को ठंडा करने, कुएं की दीवार को मजबूत करने और तेल और गैस के दबाव को नियंत्रित करने में भी मदद कर सकता है, ये सभी ब्लोआउट दुर्घटनाओं को रोकने में सहायक हैं। आंकड़ों के अनुसार, भारोत्तोलक एजेंट के रूप में बैराइट का उपयोग इसकी कुल खपत का 85% से 90% है। यह अनुप्रयोग तेल ड्रिलिंग की सुरक्षा और दक्षता सुनिश्चित करता है, साथ ही वैश्विक ऊर्जा उद्योग में बैराइट की महत्वपूर्ण स्थिति स्थापित करता है।

✱ बेरियम यौगिक का उत्पादन

बैराइट विभिन्न प्रकार के बेरियम यौगिकों के उत्पादन के लिए एक महत्वपूर्ण कच्चा माल है, जैसे बेरियम ऑक्साइड, बेरियम कार्बोनेट, बेरियम क्लोराइड और बेरियम नाइट्रेट। इन बेरियम यौगिकों का व्यापक रूप से रासायनिक अभिकर्मक, उत्प्रेरक, चीनी शोधन, कपड़ा, अग्निरोधक सामग्री, आतिशबाजी निर्माण और सिंथेटिक रबर के लिए कोगुलेंट्स के क्षेत्रों में उपयोग किया जाता है। उदाहरण के लिए, बेरियम कार्बोनेट ऑप्टिकल ग्लास के लिए एक महत्वपूर्ण कच्चा माल है, यह ग्लास के अपवर्तक सूचकांक को बढ़ा सकता है और इसके ऑप्टिकल गुणों में सुधार कर सकता है; बेरियम क्लोराइड का उपयोग कृषि कीटनाशक के रूप में किया जाता है; और बेरियम नाइट्रेट आतिशबाजी और कांच उद्योगों में महत्वपूर्ण भूमिका निभाता है।

✱ नाभिकीय विकिरण सुरक्षा सामग्री

बैराइट में बेरियम का न्यूट्रॉन इनैलास्टिक स्कैटरिंग क्रॉस सेक्शन बहुत अधिक होता है, यह न्यूट्रॉन को प्रभावी ढंग से ढाल सकता है, इसलिए इसका व्यापक रूप से परमाणु विकिरण सुरक्षा परियोजना में उपयोग किया जाता है। अल्ट्रा-फाइन बैराइट पाउडर से बने उच्च घनत्व वाले बेरियम सीमेंट, बैराइट मोर्टार और बैराइट कंक्रीट निर्माण सामग्री कुछ हद तक धातु की सीसा प्लेटों की जगह ले सकती है, परमाणु रिएक्टर को ढालने और रेडॉन-प्रूफ और एक्स-रे-प्रूफ इमारतों का निर्माण करने के लिए। यह परमाणु ऊर्जा उद्योग, परमाणु ऊर्जा संयंत्रों और एक्स-रे प्रयोगशालाओं के लिए सुरक्षा संरक्षण प्रदान कर सकता है।

✱ मिश्रित प्रवाहकीय सामग्री

डोपिंग संशोधन के माध्यम से, बैराइट को हल्के रंग के प्रवाहकीय पिगमेंट बनाने के लिए कोर सामग्री के रूप में इस्तेमाल किया जा सकता है, इससे पिगमेंट के अतिरिक्त मूल्य में काफी सुधार हो सकता है। इस पिगमेंट में न केवल आदर्श उपस्थिति रंग और चालकता है, बल्कि इसका उपयोग प्रवाहकीय कोटिंग्स, एंटीस्टेटिक कोटिंग्स, प्रवाहकीय प्लास्टिक और प्रवाहकीय रबर के उत्पादन के लिए भी किया जा सकता है, यह इलेक्ट्रॉनिक्स और विद्युत उपकरण उद्योगों के लिए सामग्री के नए विकल्प प्रदान करता है।

✱ उच्च तापमान प्रतिरोधी और घर्षण प्रतिरोधी सामग्री

विभिन्न रासायनिक संरचना, संरचनाओं के कच्चे खनिजों के साथ मिश्रित या मिश्रित बैराइट से मिश्रित मिश्र धातु डीऑक्सीडाइज़र बनाया जा सकता है। मिश्रित मिश्र धातु डीऑक्सीडाइज़र उच्च तापमान प्रतिरोधी और घर्षण प्रतिरोधी है। इस सामग्री का उच्च तापमान उद्योगों में महत्वपूर्ण अनुप्रयोग है, जैसे कि स्टील-निर्माण, यह स्टील की गुणवत्ता और प्रदर्शन में काफी सुधार कर सकता है।

✱ टाइटेनियम डाइऑक्साइड की वैकल्पिक कोटिंग

उच्च श्वेतता और स्थिरता के गुणों के साथ, बैराइट को टाइटेनियम डाइऑक्साइड के साथ मिश्रित करने के लिए कोर सामग्री के रूप में इस्तेमाल किया जा सकता है। यह संरचना टाइटेनियम डाइऑक्साइड के एकत्रीकरण की समस्या को प्रभावी ढंग से हल कर सकती है, और इसकी फोटोकैटेलिटिक संपत्ति में सुधार कर सकती है। इसके अलावा, बैराइट को टाइटेनियम डाइऑक्साइड को बदलने के लिए सीधे कोटिंग के रूप में भी इस्तेमाल किया जा सकता है, यह कोटिंग उद्योग के लिए एक नया विकल्प प्रदान करता है।

✱ मेडिकल कंट्रास्ट एजेंट

चिकित्सा क्षेत्र में, बैराइट या इसके व्युत्पन्नों का उपयोग पाचन तंत्र में कंट्रास्ट एजेंट बनाने के लिए किया जा सकता है, इससे डॉक्टरों को अधिक सटीक निर्णय लेने और चिकित्सा मानकों को बेहतर बनाने में मदद मिल सकती है।

3. सारांश

बैराइट के अनुप्रयोग की संभावना बहुत व्यापक है। प्रौद्योगिकी की उन्नति और पर्यावरण जागरूकता में सुधार के साथ, भविष्य में बैराइट के अनुप्रयोग का दायरा और अधिक विस्तारित होगा।

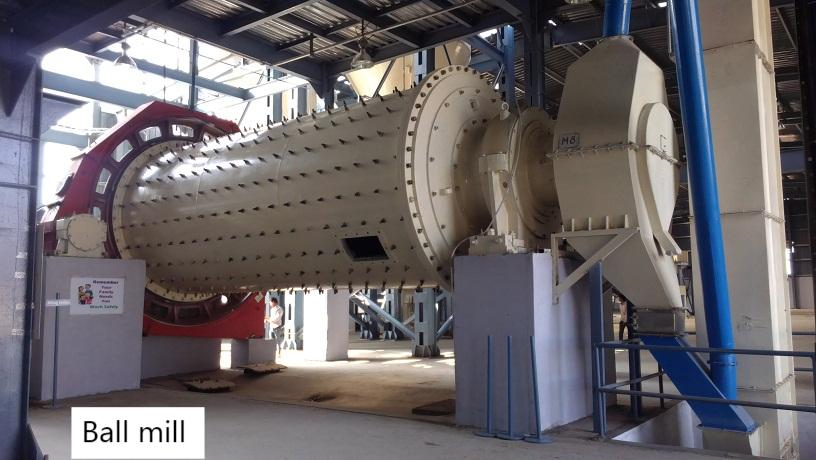

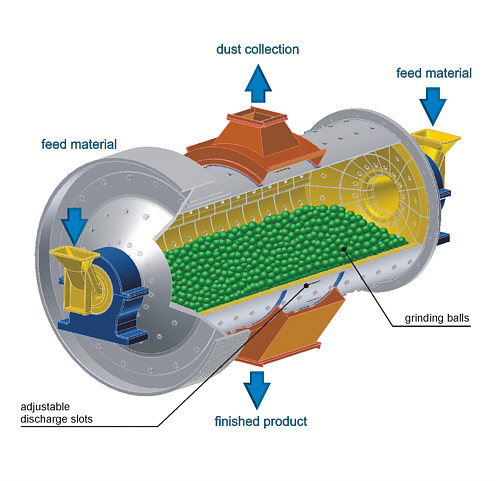

व्यावहारिक अनुप्रयोग में, विभिन्न अनुप्रयोग क्षेत्रों में कण आकार की आवश्यकताओं को पूरा करने के लिए, बैराइट को पीसने और वर्गीकृत करने की आवश्यकता होती है। पीसने और वर्गीकृत करने वाले उपकरण बैराइट के व्यावहारिक अनुप्रयोग में महत्वपूर्ण भूमिका निभाते हैं, उदाहरण के लिए: बॉल मिल और एयर क्लासिफायर।

क़िंगदाओ एपिक पाउडर मशीनरी कं, लिमिटेड। एक है उत्पादक पाउडर प्रसंस्करण उपकरण के उत्पादन में विशेषज्ञता।

इसके उत्पादों में शामिल हैं:

– मिल: बॉल मिल, रोलर मिल, जेट मिल, एयर क्लासिफायर मिल, कंपन मिल और प्रभाव मिल आदि।

- वायु वर्गीकारक: वायु वर्गीकारकों की चार श्रृंखलाएँ: एचटीएस, आईटीसी, एमबीएस और सीटीसी.

– संशोधक: पिन-मिल संशोधक, टर्बो-मिल संशोधक और तीन-रोलर-मिल संशोधक वगैरह।

– सहायक उपकरण: नियंत्रण कैबिनेट, धूल संग्रहित करने वाला और बाल्टी लिफ्ट वगैरह।

- ग्राहक अपनी आवश्यकताओं के अनुसार भी अनुकूलित कर सकते हैं, एक ग्राहक एक डिजाइन.

यदि आप बॉल मिल या एयर क्लासिफायर या अन्य उपकरण में रुचि रखते हैं क़िंगदाओ महाकाव्य, कृपया संपर्क स्टाफ सीधे तौर पर, वे सदैव आपकी सेवा में हैं।

आपके संदर्भ के लिए नीचे क़िंगदाओ एपिक की तस्वीरें दी गई हैं।