When selecting grinding media for calcium carbonate, several key factors must be considered to ensure grinding efficiency and product quality. Here’s a detailed overview of these factors:

Key Factors to Consider

1. Physical features of grinding media

Hardness:

The hardness of the grinding media usually needs to be greater than that of calcium carbonate. This is helpful for improving grinding efficiency, because when the hardness of the grinding media is higher than calcium carbonate, it can better remove defects and impurities on the surface of calcium carbonate, and then improve the grinding efficiency and product quality.

Density:

High-density grinding media is preferred, because it can generate greater impact force. This is essential for shearing and grinding harder material. Ideally, the density of grinding media should be higher than that of calcium carbonate.

2. Particle size of calcium carbonate

Feed size:

The feed size of calcium carbonate would influence the choice of grinding media. When feed size is large, using larger grinding media can better shear and grind calcium particles. This is helpful to increase mill output and reduce energy consumption.

Particle size of finished calcium:

Generally speaking, larger particle size of finished calcium requires larger diameter of grinding media, and output would be higher. Smaller grinding media is more advantageous for achieving finer particle size because it can provide more grinding surface area.

3. Properties of grinding media

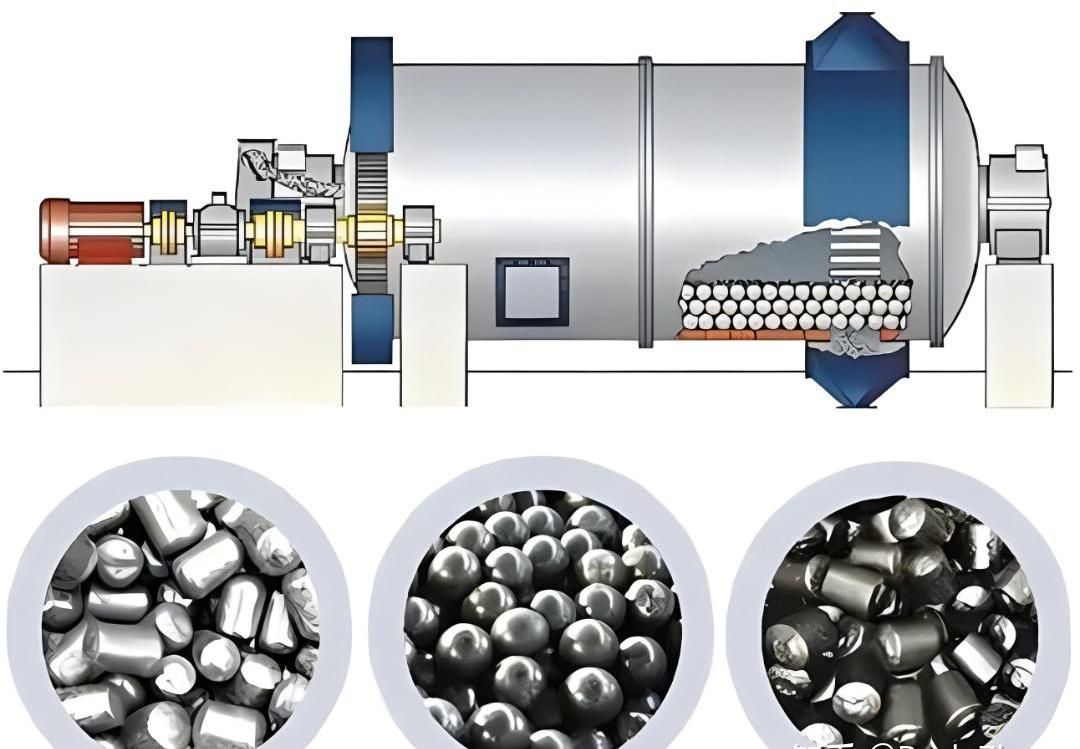

Material of grinding media:

Common grinding media for grinding calcium carbonate includes steel balls and ceramic balls. Steel balls are more suitable for grinding harder materials due to their high hardness, while ceramic balls are more suitable for ultra-fine grinding due to their high hardness, good wear resistance and strong chemical stability, especially for occasions where high product purity are required.

Chemical properties:

The chemical compatibility of the grinding media with calcium carbonate is important to avoid contamination. In order to avoid corrosion or chemical reaction, ceramic media is prefer.

Conclusion

Before grinding calcium carbonate, it is better to consider the above factors comprehensively. Select appropriate grinding media can improve both grinding efficiency and product quality.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder processing equipment. We have rich experience in grinding calcium carbonate, and the ball mill is suitable for grinding कैल्शियम कार्बोनेट and other non-metallic minerals. At the same time, the ball mill and classifier can work together to form an ball mill-classifier production line, which has high reputation among customers.

Our main products include:

– Mills: ball mill, air classifier mill(ACM), रोलर मिल, jet mill, turbo mill and impact mill, etc.

– Classifiers: include four series of air classifiers: एचटीएस, ITC, CTC and MBS.

– Surface coating modifiers: pin-mill modifier, turbo-mill modifier and three-roller-mill modifier, etc.

– Auxiliary equipment: control cabinet, dust collector and bucket elevator, etc.

– Customers can customize products according to actual needs. One customer, one design.

If you are interested in ball mill or other products from Qingdao Epic, contact our staff directly, we are always at your service.