Qu'est-ce que le sol kaolin calciné?

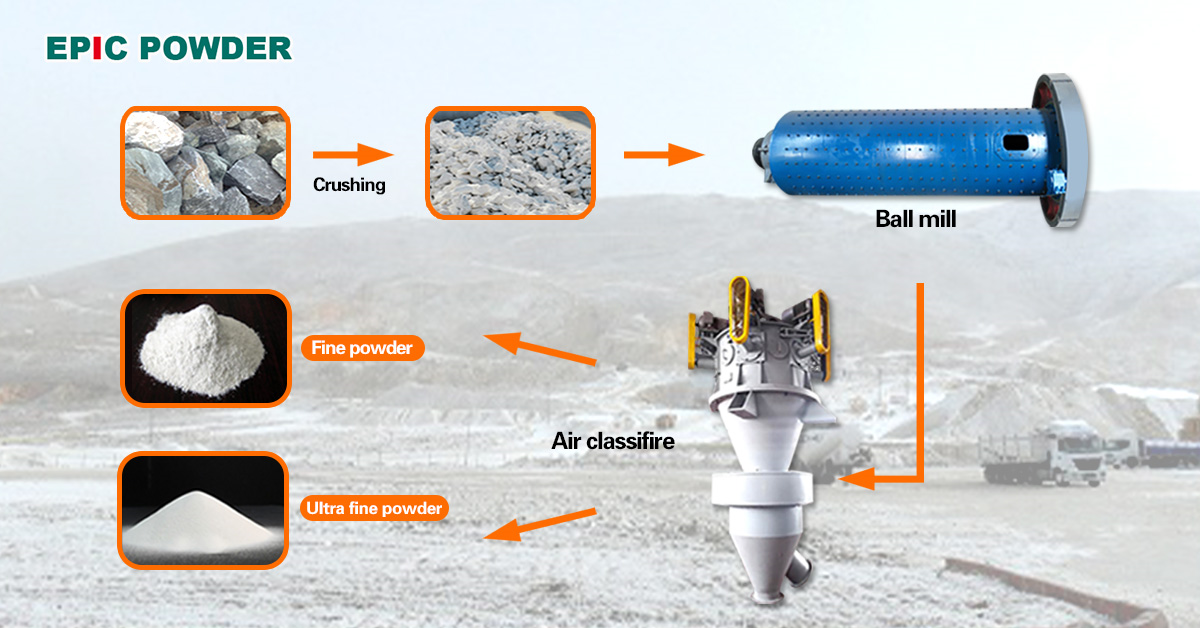

Le kaolin calciné consiste à calciner le kaolin à haute température dans un four de calcination, ce processus modifierait les propriétés physiques et chimiques du kaolin, pour répondre à certaines exigences. Le kaolin calciné moulu fait référence au kaolin calciné en poudre, il est obtenu en broyant le kaolin calciné à l'aide d'une machine de broyage, telle que broyeur à boulets, pour une meilleure application.

Le kaolin calciné moulu est principalement utilisé dans l'industrie des revêtements avec deux fonctions. L'une est pour le remplissage, l'autre pour le revêtement. Alors, quels sont les indicateurs du kaolin calciné moulu pour les revêtements ? Discutons-en ci-dessous :

Indicateurs de kaolin calciné moulu pour revêtements :

1. Blancheur

La blancheur est le principal indicateur du kaolin calciné moulu, plus elle est élevée, mieux c'est. La stabilité de la blancheur est très importante. Une blancheur différente entraînerait des différences de couleur entre différents lots de produits ayant la même formule.

2. Taille des particules

La taille des particules est en fait un indicateur superficiel et les fabricants de peinture testent rarement la taille des particules directement. Cependant, en raison de sa pertinence avec d'autres indicateurs, si la taille des particules n'est pas suffisamment fine ou non qualifiée, elle sera reflétée par d'autres indicateurs. L'exigence générale est que la proportion de particules de taille inférieure à 2 μm doit être prise en compte pour le 80%.

3. Pouvoir couvrant

Le pouvoir couvrant est l'indicateur le plus important du kaolin calciné pour les revêtements. Il dépend principalement de la taille des particules et de leur dispersibilité. Plus la taille des particules est fine, meilleure est la dispersibilité et plus le pouvoir couvrant est fort. De plus, l'indice de réfraction du kaolin calciné affectera également son pouvoir couvrant. Plus l'indice de réfraction est élevé, meilleur est le pouvoir couvrant.

4. Dispersibilité

La dispersibilité du kaolin calciné dépend principalement de la taille et de la forme des particules. Des particules de kaolin plus fines peuvent offrir une meilleure dispersibilité, car elles peuvent mieux combler les espaces entre le pigment et la charge, réduisant ainsi la floculation et l'agglomération.

5. Tamis résidu de 325 mesh

Le résidu de tamis de 325 mesh est un indicateur important. L'exigence de revêtement pour cet indicateur est inférieure à 0,02%, et plus il est petit, mieux c'est.

6. Valeur d'absorption d'huile

La valeur d'absorption d'huile du kaolin calciné est d'environ 50 g/100 g à 60 g/100 g, ce qui est modéré. La valeur d'absorption d'huile du kaolin est étroitement liée à la distribution granulométrique, à la porosité, à la surface spécifique et à la forme cristalline des particules. Lorsque la taille des particules est plus petite, la surface spécifique est plus grande et la valeur d'absorption d'huile est plus élevée.

7. Volume de sédimentation

Le volume de sédimentation reflète les performances de sédimentation du kaolin calciné dans les revêtements, il affecte directement les performances d'ouverture des boîtes de conserve des revêtements. Plus le volume de sédimentation est élevé, mieux c'est. Avec un volume de sédimentation élevé, la peinture n'est pas facile à déposer et le kaolin calciné conserverait une bonne uniformité dans les revêtements.

8. Valeur du pH

La valeur du pH reflète l'acidité et l'alcalinité du kaolin calciné. Le revêtement nécessite que sa valeur de pH soit comprise entre 6 et 8, ce qui est fondamentalement proche de la neutralité. Le pH du kaolin calciné est neutre, il n'est donc pas nécessaire de modifier la valeur du pH dans l'industrie des revêtements.

9. Résistance aux intempéries

La résistance aux intempéries du kaolin pour les revêtements comprend principalement : la résistance à la chaleur, la résistance au gel-dégel, la résistance aux chocs, la résistance à l'abrasion, la résistance au jaunissement, la résistance au vieillissement léger, la résistance aux acides et aux alcalis, etc. Ces indicateurs garantissent ensemble la stabilité et la durabilité du kaolin dans les revêtements.

Pour les indicateurs ci-dessus, la stabilité est la plus importante, sinon elle affectera les performances globales des revêtements. L'application de kaolin calciné améliore les performances des revêtements, c'est un matériau indispensable dans l'industrie des revêtements. De plus, avant d'être appliqué dans les revêtements, le kaolin calciné doit être broyé. L'équipement utilisé pour broyer le kaolin calciné est nécessaire, tel que : broyeur à boulets. Qingdao Epic Powder Machinery Co., Ltd. est un fabricant professionnel d'équipements de poudre. broyeur à boulets Les broyeurs à boulets de Qingdao Epic sont très adaptés au broyage du kaolin calciné. En particulier, le broyeur à boulets peut être combiné avec un classificateur pour former un système de circulation en boucle fermée. Il s'agit d'une ligne de production de traitement de poudre non minérale de pointe au niveau international, largement appréciée par les clients nationaux et étrangers.

Si vous avez des besoins ou des questions connexes, veuillez contacter L'épopée de Qingdao directement.