PARTIE 1

1. Inspection avant l'installation du moulin

Avant la production, une inspection complète doit être effectuée.

Vérifiez si les dispositifs de sécurité sont complets et fiables.

Vérifiez si la connexion de chaque pièce de connexion est fiable, si la machine est fermement installée sur la fondation ou le châssis et si les boulons de fixation sont desserrés ou tombent.

Ouvrez le couvercle de la machine et vérifiez s'il y a débris dans la chambre de broyage, si toutes les pièces du rotor sont intactes et si la goupille fendue est tombée ou endommagée.

Démarrez la machine et vérifiez si le sens du broyeur est cohérent avec le sens de la flèche rouge sur le couvercle de la machine.

Vérifiez le système de lubrification.

2. Essai de démarrage

Si tous les aspects répondent aux exigences, démarrez l'essai. Après un essai à vide d'une heure, vérifiez l'élévation de température du roulement et vérifiez si les pièces sont anormales. L'élévation de température ne doit pas dépasser 35 °C. En général, un thermomètre ordinaire peut être inséré dans le pot à beurre pour l'inspection (la température mesurée par le thermomètre moins la température ambiante est la valeur d'élévation de température). Lorsque toutes les pièces répondent aux exigences, la machine peut être mise en production. Pour la mise en service initiale de la machine, il est préférable de traiter d'abord les cosses ou le foin pour nettoyer l'huile et la rouille à l'intérieur de la machine.

PARTIE 2

Qualité partielle du broyage

1. Caractéristiques de la matière première

Les usines d'aliments pour animaux doivent généralement broyer divers matériaux recyclés et matières premières végétales, telles que la paille, les tiges de coton, les tiges de maïs, le maïs, la farine de soja et le blé.

2. Exigences relatives aux aliments pour animaux

L'augmentation de la surface de l'aliment et l'ajustement de la taille des particules peuvent améliorer la digestibilité, mieux absorber les nutriments et, en fin de compte, augmenter le rapport aliment/viande. Par exemple, l'alimentation des poulets ne doit pas être trop fine, car les poulets aiment manger des granulés ou des grains moulus. Les aliments grossiers et fins peuvent être mélangés ensemble, et ils doivent être riches en huile. Alors que l'alimentation des porcs, plus elle est fine, mieux c'est, elle ne nécessite pas de teneur élevée en huile.

3. Propriétés physiques des matières premières

Les matières premières des aliments pour animaux sont généralement composées d'amidon, de protéines, de fibres, de minéraux, d'huile et d'eau. Les principaux facteurs affectant les propriétés physiques sont la température et la température du matériau (le matériau est plus cassant à basse température, donc le fonctionnement de nuit peut économiser de l'énergie). La difficulté du broyage fin : fibre>protéine>amidon>minéraux.

La teneur en huile et en eau affecte la taille des particules broyées : plus la teneur en huile et en eau est élevée, plus la finesse de broyage est grossière. Les méthodes les plus couramment utilisées pour traiter les matières à forte teneur en humidité et en matières grasses sont le broyage mixte et le broyage congelé.

PARTIE 3

Le moulin lui-même

Vitesse de l'équipement

La vitesse a une grande influence sur l'effet de broyage et la consommation d'énergie de l'équipement. En règle générale, une vitesse trop élevée ou trop faible entraînera à la fois une réduction de l'effet de broyage et une augmentation de la consommation d'énergie de l'équipement. Il est donc nécessaire d'optimiser la vitesse du broyeur. En règle générale, la vitesse est liée à la dureté et à l'humidité du matériau.

Dans les applications pratiques, pour les matériaux à dureté élevée, la vitesse peut être augmentée de manière appropriée. Pour les matériaux à humidité élevée, la vitesse doit être réduite de manière appropriée. De plus, pour des raisons de sécurité, la vitesse ne doit pas être excessivement élevée pour éviter tout dommage ou accident. La vitesse doit dépendre de la dureté, de l'humidité, de la taille et de la composition du matériau.

Le rotor et la base

Le rotor et la base sont également des éléments clés de l'équipement. En général, l'équilibre dynamique du rotor est contrôlé à moins de 5 g (la norme nationale est à moins de 10 g).

Résumé

L'équipement de broyage joue un rôle essentiel dans le traitement des aliments pour animaux. Il améliore non seulement le taux de digestion et d'absorption des bétail et la volaille, mais répond également aux besoins de différents objets d'alimentation. C'est un équipement indispensable dans le traitement des aliments.

Qingdao Epic Powder Machinery Co., Ltd. est un fabricant professionnel de machines à poudre. Les produits comprennent :

➊ Broyeurs : broyeurs à jet, broyeurs classificateurs à air, broyeur à boulets, broyeur à vibrations, broyeur à rouleaux etc.

➋ Divers classificateurs d'air.

➌ Divers modificateurs de revêtement de surface.

➍ Équipements auxiliaires connexes, sch comme armoire de commande et élévateur à godets etc.

Parmi eux, les broyeurs tels que les broyeurs classificateurs à air conviennent au traitement et au broyage des aliments pour animaux. Ils peuvent traiter des aliments pour animaux de différentes tailles de particules et ont une large gamme d'applications.

Si vous avez des besoins ou des questions connexes, veuillez contacter le personnel depuis L'épopée de Qingdao directement, ils sont toujours à votre service.

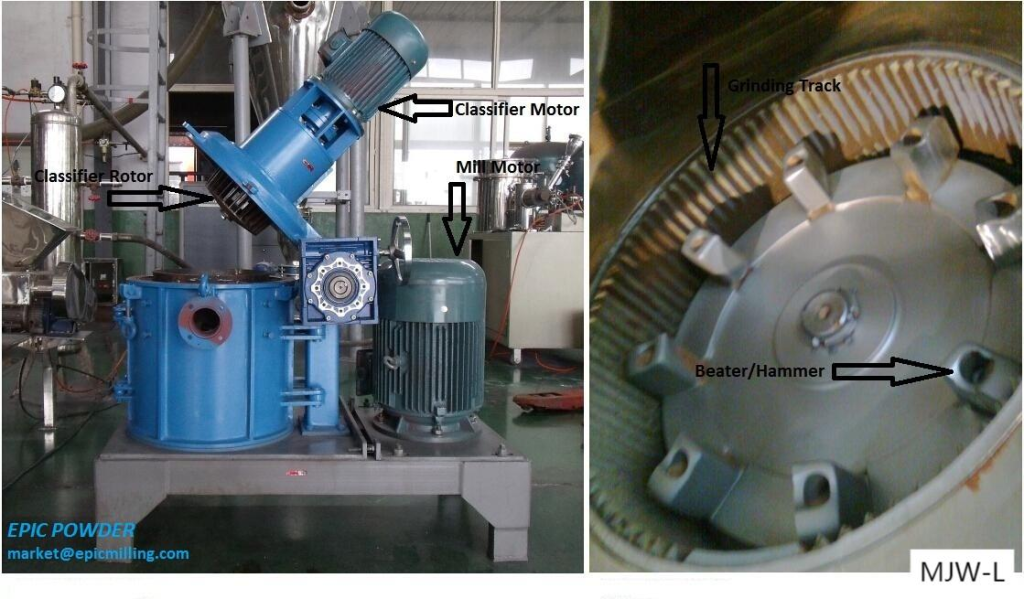

Vous trouverez ci-dessous plusieurs types de broyeurs classificateurs à air pour votre référence.