Une poudre est un assemblage de nombreuses petites particules. Elle présente de nombreuses surfaces discontinues et une grande surface spécifique. La taille des particules est généralement inférieure à 1000 μmLa poudre possède certaines propriétés physiques, telles que la fluidité, le remplissage, la cohésion et la chargeabilité. La fluidité est la base de l'ingénierie des poudres et constitue un indicateur important de leurs performances.

Plusieurs facteurs influencent la fluidité de la poudre. Voici une brève analyse de ces facteurs.

Facteurs affectant la fluidité de la poudre

1 Taille des particules et distribution granulométrique

La taille des particulesLa fluidité de la poudre est étroitement liée à la granulométrie. En général, des particules de 10 à 100 microns améliorent la fluidité. Des particules trop grandes ou trop petites peuvent nuire à la fluidité de la poudre.

Distribution granulométriqueL'uniformité de la distribution granulométrique est essentielle à la fluidité des poudres. Une poudre uniformément répartie présente une meilleure fluidité, tandis qu'une distribution granulométrique inégale peut entraîner une diminution de la fluidité.

2. Forme des particules

Même avec une granulométrie identique, des poudres de formes différentes présentent une fluidité différente. Les particules sphériques offrent la meilleure fluidité, car leur surface de contact est la plus faible. En revanche, les particules en flocons ou en branches présentent davantage de points de contact, ce qui se traduit par une surface de contact plus importante et une force de cisaillement plus importante, ce qui rend la fluidité de la poudre médiocre.

③ Porosité

La porosité a un effet significatif sur la fluidité de la poudre. Plus la porosité est élevée, plus la masse volumique apparente de la poudre est faible et meilleure est sa fluidité ; à l'inverse, plus la porosité est faible, plus la masse volumique apparente est élevée et moins la fluidité est élevée.

④ Température

Lorsque la température varie, la fluidité de la poudre augmente d'abord, puis diminue. À basse température, la densité des particules augmente avec la température, ce qui contribue à améliorer la fluidité de la poudre. En revanche, lorsque la température est trop élevée, l'adhérence des poudres augmente, ce qui entraîne une faible fluidité.

⑤ Humidité

Lorsque la teneur en humidité de la poudre est faible, elle est présente sous forme d'eau adsorbée, ce qui a peu d'effet sur la fluidité. Lorsque la teneur en humidité continue d'augmenter, un film d'eau se forme entre les particules. Ce film augmente la résistance au mouvement relatif entre les particules, ce qui entraîne une diminution de la fluidité de la poudre. Lorsque la teneur en humidité dépasse la limite d'eau moléculaire maximale, la fluidité de la poudre se dégrade rapidement, voire disparaît complètement.

Comment améliorer la fluidité des poudres ? La modification du revêtement de surface est une méthode possible.

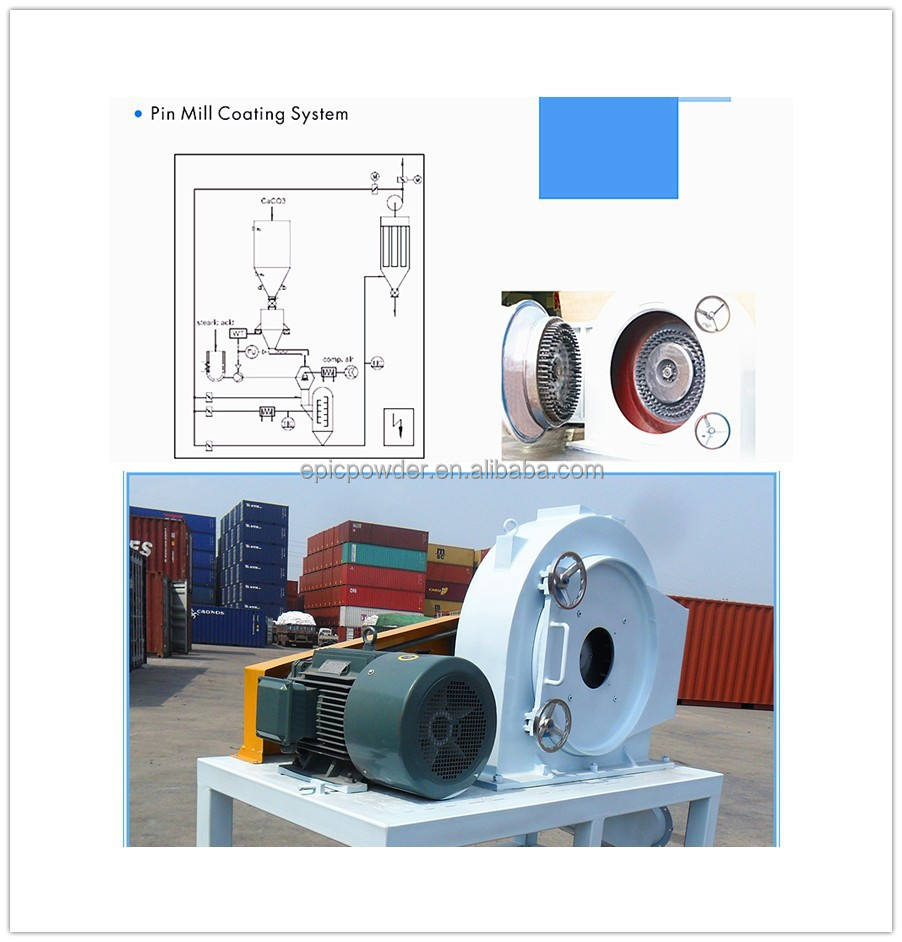

Le principe de la modification du revêtement de surface consiste à recouvrir la surface des particules d'une couche de modificateur. Ce modificateur présente généralement une grande surface spécifique et une structure multiprocesseur, ce qui permet de disperser efficacement les particules, de réduire l'adhérence et l'agrégation entre elles, et d'améliorer la fluidité de la poudre.

Qingdao Epic Powder Machinery Co., Ltd est un fabricant Nous sommes spécialisés dans la production d'équipements de traitement des poudres. Les équipements de revêtement de surface font partie de notre gamme de produits. il comprend : modificateur de broyeur à broches, modificateur de turbo-broyeur et modificateur de broyeur à trois rouleaux.

Nos principaux produits comprennent :

– Moulins: broyeur à boulets, broyeur à rouleaux, broyeur classificateur à air (ACM), broyeur à jet, broyeur turbo et broyeur à impact, etc.

– Classificateurs:comprend quatre séries de classificateurs à air : HTS, CCI, MBS et CTC.

– Revêtement de surface modorants: modificateur de broyeur à broches, modificateur de turbo-broyeur et modificateur de broyeur à trois rouleaux, etc.

– Équipement auxiliaire: armoire de commande, convoyeur à bande et élévateur à godets, etc.

– Les clients peuvent personnaliser les produits en fonction de leurs besoins réels. Un client, un design.

Si vous êtes intéressé par des équipements de revêtement de surface ou d'autres produits de L'épopée de Qingdao, Contactez notre équipe directement, nous sommes toujours à votre service.

Vous trouverez ci-dessous des photos de Qingdao Epic pour votre référence.