¿Qué es el talco?

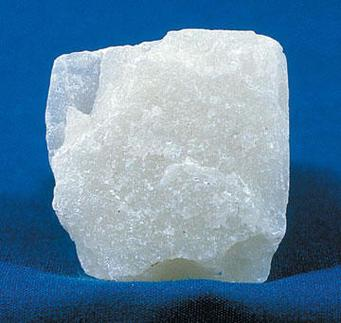

Talco is one kind of mineral formed by hydrothermal alteration. Magnesium-rich minerals usually become talc after hydrothermal alteration. Talc is common silicate mineral. Since talc is ultimately used in powder form, fine grinding is a necessary process for talc. The Mohs hardness of talc is 1, so it is easier to grind. Fine-grinding equipment of talc would be mentioned beblow:

Ultra-fine talc powder with mesh over 325 is one of the ultra-fine powders with largest application worldwide, it is widely used in Fabricación de papel, plastics, rubber, paints and coatings, cosmetics and ceramics.

Equipo utilizado para molienda fina de talco

At present, the processing of ultra-fine talc mainly adopts dry processing. The equipment of dry processing mainly includes: impact mill, jet mill, vibration mill, roller mill and ball mill.

El procedimiento de molienda fina del talco.

In short, the processing procedure is: talc block – coarse crushing – drying – medium crushing – fine grinding – ultra-fine grinding – cyclone aggregation – packaging. Specifically, the procedure is as follows: first, pre-crush talc stone through coarse crushing, then send crushed talc to vertical dryer via bucket elevator. Next, crush the dried feed by hammer crusher, after crushing, send ground feed to Raymond mill for find-grinding. Next, ultra-fine grinding of ground powder by roller mill, ball mill or jet mill. The final product fineness can reach 500-5000 mesh (d97=30-5um). After ultra-fine grinding, the talc powder are classified by classifier and finally collected through cyclone collector.

Los estudios han demostrado que se producen varios cambios en el polvo de talco después de la molienda ultrafina. Además de un cambio visible en el tamaño de las partículas, aumenta el área de superficie específica, mejora la blancura y la actividad del polvo mejora significativamente. La molienda ultrafina es un importante método de procesamiento profundo para materiales minerales no metálicos. La selección del equipo de molienda adecuado es crucial para mejorar la eficiencia del procesamiento y la calidad del producto.

Resumen

Los estudios han demostrado que se producen varios cambios en el polvo de talco después de la molienda ultrafina. Además de un cambio visible en el tamaño de las partículas, aumenta el área de superficie específica, mejora la blancura y la actividad del polvo mejora significativamente. La molienda ultrafina es un importante método de procesamiento profundo para materiales minerales no metálicos. La selección del equipo de molienda adecuado es crucial para mejorar la eficiencia del procesamiento y la calidad del producto.

Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer of powder processing equipment. The products include: jet mill, ball mill, vibration mill, molino de rodillos, various classifiers, surface coating modifiers and related auxiliary equipment, such as dust collector. Qingdao Epic has always adhered to the principle of reliable quality, low price, first-class after-sales service, and the concept of one customer one design. Ball mill from Qingdao Epic can be well used in grinding talc powder. It can be combined with single classifier or multiple classifiers for classifying powders with different fineness. The ball mill-classifier production line is advanced processing line for non-mineral powders. It has high reputation among customers both home and abroad.

If you have related demands or questions, contact staff of Qingdao Epic directly, they are always at your service.

A continuación se muestran varias fotografías para su referencia.