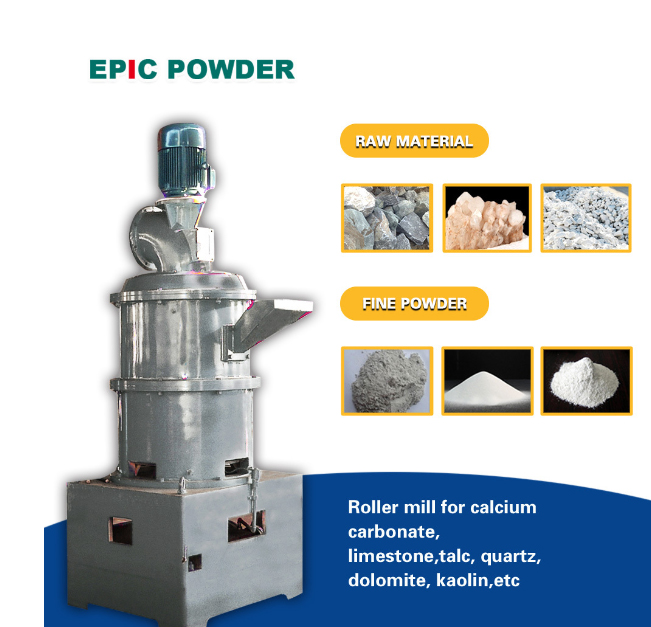

مطحنة الأسطوانات هي معدات طحن المساحيق التي تستخدم مبادئ التأثير والضغط والطحن لسحق المواد. تتكون مطحنة الأسطوانات من عدة مكونات رئيسية تعمل معًا لطحن وسحق مجموعة متنوعة من المواد بشكل فعال.

المكونات الرئيسية لمطحنة الأسطوانة

1. أسطوانة الطحن

أسطوانة الطحن هي المكون الرئيسي لمطحنة الأسطوانة. وهي أسطوانية الشكل، وتدور حول محور مركزي. وعادة ما تكون الأسطوانات مصنوعة من الفولاذ عالي الجودة، ومطلية بمادة مقاومة للتآكل، وقد يختلف عدد الأسطوانات حسب تصميم المطحنة، اثنتان أو أربع أو ست.

2. حلقة الطحن

حلقة الطحن هي أساس طاحونة الأسطوانة. فهي تتحمل وزن المادة التي يتم طحنها والقوة التي تمارسها الأسطوانات. عادة ما تكون حلقة الطحن مصنوعة من مادة مقاومة للتآكل والتآكل، لضمان استقرارها ومتانتها أثناء الاستخدام.

3. نظام القيادة

يتكون نظام القيادة من المحرك وعلبة التروس والوصلة. يوفر المحرك الطاقة لـ تناوب طاولة الطحن والأسطوانة؛ يعمل صندوق التروس على تقليل سرعة المحرك إلى مستوى مناسب للطحن؛ ويربط الوصل بين هذه المكونات لضمان نقل الطاقة بكفاءة.

4. المصنف

يقع المصنف فوق طاولة الطحن ويُستخدم بشكل أساسي لتصنيف المواد. عادةً ما يشتمل هيكل المصنف على منفذ تغذية وعجلة تصنيف وشاشة وما إلى ذلك.

5. المروحة

الوظيفة الرئيسية للمروحة في مطحنة الأسطوانة هي المساعدة في تفريغ المساحيق الدقيقة في الوقت المناسب، ومنع انسداد مجرى الهواء.

6. فاصل

الوظيفة الرئيسية للفاصل هي فصل المواد. ويمكنه ضمان تلبية حجم الجسيمات للمتطلبات. على وجه التحديد، يفصل الفاصل الجسيمات الخشنة عن الجسيمات الدقيقة. تعود الجسيمات الخشنة إلى حجرة الطحن لإعادة الطحن، بينما تدخل الجسيمات المؤهلة إلى المجمع وتصبح منتجًا نهائيًا.

7. جامع الغبار النبضي

الوظيفة الرئيسية لمجمع النبضات هي جمع وتصفية الغبار الناتج أثناء الإنتاج. وهو يضمن أن المنتج النهائي خالٍ من تلوث الغبار.

لا يمكن ضمان التشغيل الفعال والمستقر لمطحنة الأسطوانة إلا عندما تعمل المكونات المذكورة أعلاه بشكل طبيعي وتتعاون مع بعضها البعض. وباختصار، يلعب كل مكون دورًا مهمًا في التشغيل السليم لمطحنة الأسطوانة.

شركة تشينغداو إبيك لآلات المساحيق المحدودة هو الشركة المصنعة متخصصة في إنتاج آلات المسحوق.

منتجاتنا الرئيسية تشمل:

– المطاحن: مطحنة الأسطوانة, مطحنة الكرات، مطحنة تصنيف الهواء (ACM)، مطحنة نفاثة، مطحنة توربينية ومطحنة تأثير، الخ.

– المصنفات:تتضمن أربع سلاسل من مصنفات الهواء: هيئة تحرير الشام, مركز التجارة الدولية، MBS وCTC.

– طلاء السطح ممُعَطِّلات: معدل مطحنة الدبوس, معدل طاحونة التوربو ومعدل طاحونة ثلاثية الأسطوانات، وما إلى ذلك.

– المعدات المساعدة: خزانة التحكم, جامع الغبار ومصعد الدلو، وما إلى ذلك.

– يمكن للعملاء تخصيص المنتجات وفقًا لاحتياجاتهم الفعلية. عميل واحد، تصميم واحد.

إذا كنت مهتمًا بمطحنة الأسطوانة أو المنتجات الأخرى من ملحمة تشينغداو, اتصل بموظفينا مباشرة، نحن في خدمتكم دائمًا.