1. المقدمة

الأقمشة غير المنسوجة مصنوعة من ألياف صناعية. في السنوات الأخيرة، مع خصائص مقاومة الرطوبة وخفة الوزن وعدم السمية والتكلفة المنخفضة، دخلت الأقمشة غير المنسوجة تدريجياً في نظر الناس وتم استخدامها على نطاق واسع في العديد من المجالات. يمكن استخدام كربونات الكالسيوم فائقة الدقة، كحشو مسحوق غير عضوي يستخدم على نطاق واسع، في إنتاج الأقمشة غير المنسوجة. لا يمكنها فقط تقليل تكاليف الإنتاج، بل إنها تعمل أيضًا على تحسين أداء الأقمشة غير المنسوجة، لذا فإن دور كربونات الكالسيوم فائقة الدقة في الأقمشة غير المنسوجة مهم. بشكل عام، يجب ألا تتجاوز كمية كربونات الكالسيوم المضافة 5% من وزن المنتج.

2. دور كربونات الكالسيوم فائقة الدقة في الأقمشة غير المنسوجة

تعزيز صلابة المواد

إن إضافة نسبة معينة من كربونات الكالسيوم فائقة الدقة يمكن أن يعزز بشكل كبير صلابة القماش غير المنسوج ويجعل أداء المنتج أكثر استقرارًا.

يحسن مقاومة التمزق

إن إضافة كربونات الكالسيوم فائقة الدقة أثناء إنتاج الأقمشة غير المنسوجة يمكن أن يزيد بشكل فعال من مقاومة القماش للتمزق ويحسن جودته بشكل عام.

زيادة المرونة

يمكن أن يؤدي إضافة كربونات الكالسيوم فائقة الدقة إلى جعل القماش غير المنسوج أكثر نعومة ومرونة، ومناسبًا لاستخدامات خاصة معينة.

خفض التكاليف

باعتبارها مادة مالئة مسحوقة غير عضوية ورخيصة، يمكن لكربونات الكالسيوم فائقة الدقة أن تقلل من تكاليف إنتاج الأقمشة غير المنسوجة.

3. مؤشر كربونات الكالسيوم

عند اختيار كربونات الكالسيوم كحشو للأقمشة غير المنسوجة، يمكن اختيار كربونات الكالسيوم بالمؤشر التالي:

① حجم الجسيمات: حجم الجسيمات المفضل هو 4-8 اممم.

② الرطوبة: المتطلب العام هو ≤0.5%.

③كلما زاد البياض، كان ذلك أفضل. بشكل عام، يجب أن يكون البياض ≥ 90%. يمكن أن يصل بياض كربونات الكالسيوم عالية الجودة إلى أكثر من 95%.

④يجب أن تكون قيمة امتصاص الزيت منخفضة، والقيمة المرجعية هي ≦20-23 جم/100 جم.

4. التطبيق

يتم استخدام الأقمشة غير المنسوجة المضاف إليها كربونات الكالسيوم فائقة الدقة على نطاق واسع في العديد من المجالات، مثل التصميمات الداخلية للسيارات، المراتبالأثاث ومواد التعبئة والتغليف. إن إضافة كربونات الكالسيوم يمكن أن تجعل منتجات الأقمشة غير المنسوجة أقوى وأكثر نسيجًا.

كحشو، فإن حجم الجسيمات ونقاء كربونات الكالسيوم فائقة الدقة لها تأثير مهم على أداء الأقمشة غير المنسوجة. من أجل ضمان جودة وأداء الأقمشة غير المنسوجة، يجب سحق الكالسيوم فائق الدقة وتصنيفه. من خلال الطحن والتصنيف، يمكن أن يلعب الكالسيوم فائق الدقة دورًا أفضل في الأقمشة غير المنسوجة.

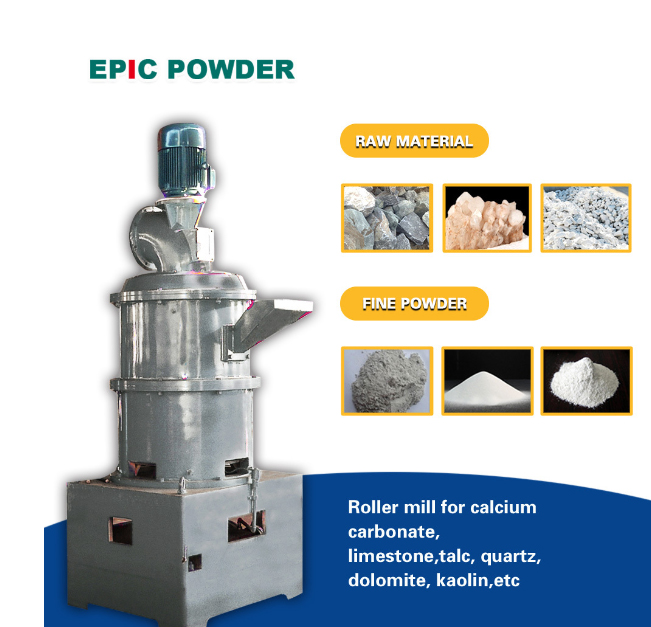

شركة تشينغداو إبيك لآلات المساحيق المحدودة هو الشركة المصنعة متخصصة في إنتاج آلات المسحوق. طاحونة الأسطوانة وجهاز التصنيف الهوائي من شركتنا مناسبان لطحن وتصنيف الكالسيوم فائق الدقة، مع أداء ممتاز وأسعار معقولة.

منتجاتنا الرئيسية تشمل:

– المطاحن: مطحنة الأسطوانة, مطحنة الكرات، مطحنة تصنيف الهواء (ACM)، مطحنة نفاثة ومطحنة توربينية وما إلى ذلك.

– مصنفات الهواء:تتضمن أربع سلاسل: هيئة تحرير الشام, مركز التجارة الدولية، MBS و CTC .

– تعديلات طلاء السطح: معدل مطحنة الدبوس, معدل طاحونة التوربو و معدل طاحونة ثلاثية الأسطوانات، إلخ.

– المعدات المساعدة: خزانة التحكم, جامع الغبار ومصعد الدلو، وما إلى ذلك.

– يمكن للعملاء تخصيص المنتجات وفقًا لاحتياجاتهم الفعلية. عميل واحد، تصميم واحد.

إذا كانت لديك طلبات ذات صلة بمطحنة الأسطوانة أو المصنف الهوائي أو المنتجات الأخرى من ملحمة تشينغداو, اتصل بموظفينا مباشرة، نحن في خدمتكم دائمًا.

فيما يلي منتجات من Qingdao Epic للرجوع إليها.