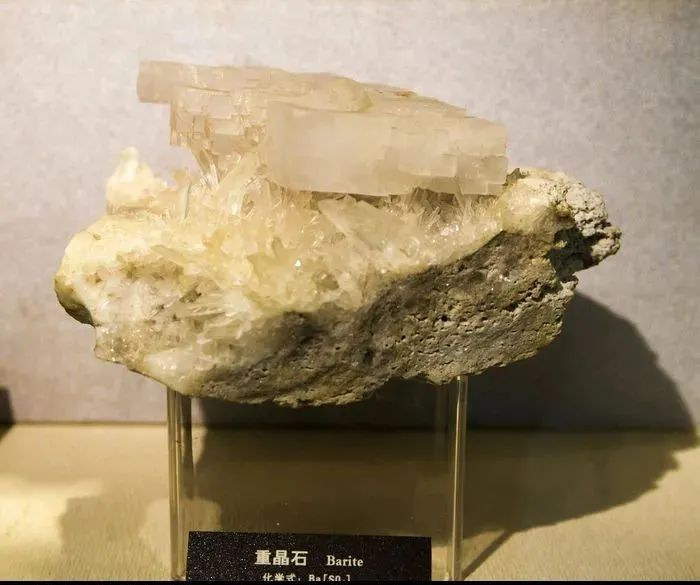

الباريت هو أكثر معادن الباريوم شيوعًا، ومكونه الرئيسي هو كبريتات الباريوم. عادةً ما يكون أبيض اللون ولامعًا، ولكنه قد يبدو رماديًا أو أحمر فاتحًا أو أصفر فاتحًا بسبب الشوائب. يتميز الباريت بخصائص كيميائية مستقرة، وهو غير سام، وغير قابل للذوبان في الماء أو... حمض الهيدروكلوريكمن خلال معالجة خام الباريت الخام عبر الطحن والتصنيف وخطوات أخرى، يمكن الحصول على مسحوق الباريت ذي الجودة الكيميائية. لفهم أعمق، سنتحدث لاحقًا عن استخدامات مسحوق الباريت وتعديلاته.

تطبيق مسحوق الباريت

مسحوق الباريت مادة خام معدنية غير معدنية مهمة ذات تطبيقات واسعة. مجالات تطبيقه الرئيسية هي صناعة البترول والصناعات الكيميائية. في صناعة البترول، يُستخدم مسحوق الباريت كعامل ترجيح لطين حفر آبار النفط والغاز؛ وفي الصناعة الكيميائية، يُستخدم كمادة خام لتصنيع مختلف المنتجات الكيميائية المحتوية على الباريوم، مثل كربونات الباريوم وكبريتات الباريوم. أكسيد الباريوم.

بالإضافة إلى ذلك، يُمكن استخدام مسحوق الباريت في صناعة الدهانات لزيادة سُمكها ومتانتها ومتانتها. كما يُمكن استخدامه في صناعة المطاط والبلاستيك لتحسين صلابة منتجات المطاط والبلاستيك ومقاومتها للتآكل والشيخوخة.

تعديل الباريت مسحوق

نظرًا لأن سطح مسحوق الباريت محب للماء، في حين أن معظم المواد البوليمرية كارهة للماء، فمن الصعب توزيع مسحوق الباريت بالتساوي في المواد البوليمرية، وهذا يؤثر على الأداء الشامل لـ مادة مركبةمن أجل تحسين أدائه بشكل أكبر وتوسيع مجالات تطبيقه، يجب تعديل سطح مسحوق الباريت.

في الوقت الحاضر، الطريقة الأكثر شيوعا المستخدمة لتعديل مسحوق الباريت هي تعديل الطلاء السطحي.

يشير تعديل طلاء سطح مسحوق الباريت إلى تقنية تُشكّل طبقة طلاء ثابتة وموحدة على سطح جزيئات الباريت بطرق فيزيائية أو كيميائية لتغيير خصائصه السطحية. يتميز سطح مسحوق الباريت المعدّل بأنه محب للماء وكاره للزيوت، مما يُحسّن قابليته للتشتت والتقارب في المواد المركبة.

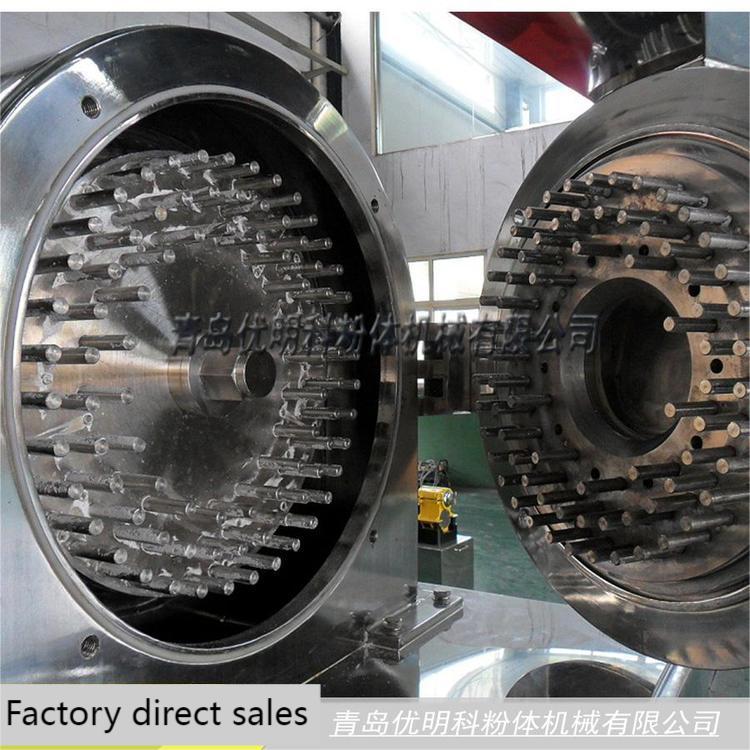

شركة تشينغداو إبيك لآلات المساحيق المحدودة هو الشركة المصنعة متخصصون في إنتاج آلات المساحيق. من منتجاتنا معدات تعديل طلاء الأسطح، وتشمل ثلاث سلاسل: معدل مطحنة الدبوس, معدل طاحونة التوربو، و معدل طاحونة ثلاثية الدواراتيمكن لهذه المعدات إكمال عملية الطلاء وتشكيل الفيلم في وقت قصير، مع أداء ممتاز واستهلاك منخفض للطاقة، وخاصةً معدل مطحنة الدبوس، الذي يحظى بشعبية كبيرة بين العملاء.

منتجاتنا الرئيسية تشمل:

– المطاحن: مطحنة الأسطوانة, مطحنة الكرات، مطحنة تصنيف الهواء (ACM)، مطحنة نفاثة ومطحنة توربينية وما إلى ذلك.

– هواء المصنفات:تتضمن أربع سلاسل: هيئة تحرير الشام, مركز التجارة الدولية، MBS و CTC .

– تعديلات طلاء السطح: معدل طاحونة دبوسية، معدل طاحونة توربينية ومعدل طاحونة ثلاثية الدوارات، وما إلى ذلك.

– المعدات المساعدة: خزانة التحكم, جامع الغبار و مصعد دلو، إلخ.

– يمكن للعملاء تخصيص المنتجات وفقًا لاحتياجاتهم الفعلية. عميل واحد، تصميم واحد.

إذا كانت لديك مطالب ذات صلة بتعديل المعدات أو المنتجات الأخرى من ملحمة تشينغداو, اتصل بموظفينا مباشرة، نحن في خدمتكم دائمًا.

فيما يلي منتجات من Qingdao Epic للرجوع إليها.