كربونات الكالسيوم، كحشو غير عضوي، يستخدم على نطاق واسع في صناعات البلاستيك والمطاط والطلاءات صناعة الورق. بياض يعتبر بياض الكربونات أحد المؤشرات المهمة لقياس جودته، حيث لا يؤثر البياض على مظهر المنتج فحسب، بل يؤثر أيضًا بشكل مباشر على القيمة السوقية وأداء التطبيق للمنتج. ستناقش هذه المقالة العوامل الرئيسية التي تؤثر على بياض الكربونات وتقترح الحلول المناسبة.

العوامل الرئيسية المؤثرة على البياض

1. جودة المواد الخام

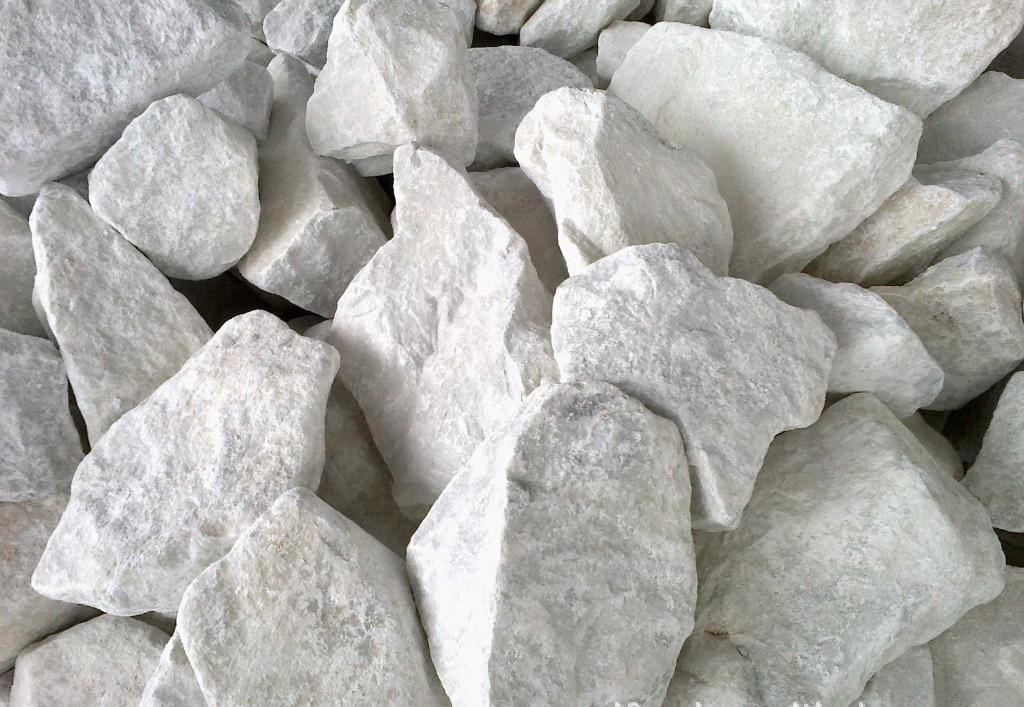

الحجر الجيري يعتبر عامل البياض من أهم العوامل التي تؤثر على بياض كربونات الكالسيوم. حيث أن الشوائب مثل الحديد والمنجنيز وحمض الهيدروكلوريك غير القابلة للذوبان ستقلل بشكل كبير من بياض المنتج. فقط عندما يكون محتوى الحديد ≤0.12% ومحتوى المنجنيز ≤0.006% ومحتوى حمض الهيدروكلوريك غير القابل للذوبان ≤0.30%، يمكن إنتاج كربونات الكالسيوم ذات البياض المقبول. يمكن لخبراء فحص المواد الخام إعطاء حكم أولي على نقاء الحجر الجيري بناءً على مظهره. عادةً ما يكون الحجر الجيري ذو الألوان السماوية أو الرمادية الفاتحة أكثر نقاءً، في حين أن الحجر الجيري الذي يحتوي على المزيد من الشوائب مثل الحديد والمنجنيز يكون منقوشًا أو مرقطًا بألوان صفراء أو بنية أو وردية.

2. اختيار الوقود

في إنتاج كربونات الكالسيوم، يعد اختيار الوقود أمرًا بالغ الأهمية أيضًا. سيؤثر محتوى الشوائب مثل الكبريت والرماد في الأنثراسايت بشكل مباشر على بياض كربونات الكالسيوم. يجب أن يكون محتوى الكبريت في الأنثراسايت للإنتاج ≤1.5%، ويجب أن يكون محتوى الرماد ≤25%، ويجب أن يكون محتوى الشوائب الأخرى ≤2.0%، ثم يمكن تلبية متطلبات إنتاج كربونات الكالسيوم ذات البياض المؤهل.

3. تكنولوجيا الإنتاج

❊ حالة التكليس

تؤثر حالة التكليس للجير الحي بشكل كبير على بياض كربونات الكالسيوم. يمكن تحسين بياض كربونات الكالسيوم عن طريق التحكم الصارم في درجة حرارة التكليس ووقته لتجنب الإفراط في حرق الجير الحي، فضلاً عن إزالة الشوائب مثل خبث الكوك ونوى الكوك.

❊ عملية الكربنة

أثناء عملية الكربنة، يجب أن يكون التفاعل بين Ca(OH)2 وCO2 كاملاً لضمان عدم عودة القلويات وعدم التكتل، وبالتالي تحسين قابلية التشتت ودقة الجسيمات وتوحيد توزيع جزيئات البلورات. هذه أيضًا إحدى الطرق الرئيسية لتحسين بياض المنتج.

4. حجم الجسيمات ومحتوى الماء في الخام

كلما كان حجم جزيئات الخام أدق، كلما كان البياض أعلى. ومع ذلك، فإن المنتجات المعدنية ذات الاستخدامات المختلفة لها متطلبات مختلفة لحجم الجسيمات، لذلك فهي تحتاج إلى دراسة شاملة. بالإضافة إلى ذلك، فإن محتوى الماء في الخام هو أيضًا عامل مهم يؤثر على البياض. يمكن أن يؤدي تقليل محتوى الماء في الخام إلى تحسين بياض كربونات الكالسيوم بشكل فعال.

ردًا على المشكلات المذكورة أعلاه، يمكننا اعتماد الحلول التالية

1. اختيار المواد الخام عالية الجودة

اختيار الحجر الجيري الذي يحتوي على نسبة منخفضة من الشوائب من الحديد والمنجنيز كمواد خام، وضمان نقاوته من خلال الفحص والتصنيف الصارمين. وفي الوقت نفسه، من خلال التحليل الكيميائي لضمان أن جميع المؤشرات تلبي متطلبات الإنتاج.

2. تحسين اختيار الوقود

اختر الفحم منخفض الكبريت والرماد كوقود لتقليل التأثير السلبي على البياض. علاوة على ذلك، اختبر جودة الوقود بانتظام لضمان استقرار جودة الوقود.

3. تحسين تكنولوجيا الإنتاج

✬ عملية التكليس

تحسين درجة حرارة التكليس ووقته لضمان جودة الجير الحي. وفي الوقت نفسه، تحسين كفاءة التكليس والحد من حدوث الحرق الزائد من خلال تحسين معدات التكليس.

✬ عملية الكربنة

تحسين نقاء غاز ثاني أكسيد الكربون في الفرن لضمان التفاعل الكامل بين Ca(OH)2 وثاني أكسيد الكربون. وفي الوقت نفسه، تعزيز مراقبة عملية الكربنة لضمان عدم عودة القلويات وعدم التكتل.

4. الطحن الدقيق والتصنيف

بخير طحن إن تصنيف كربونات الكالسيوم يمكن أن يحسن من تجانس ودقة الجسيمات. إن تحسين بياض كربونات الكالسيوم بالطرق الفيزيائية يعد وسيلة فعالة لتحسين جودة المنتج.

5. المعالجة الكيميائية

من خلال المعالجة الكيميائية المناسبة، مثل الغسيل بالحامض والغسيل بالقلويات، يتم إزالة الشوائب في كربونات الكالسيوم وتحسين نقائها. يمكن للمعالجة الكيميائية تحسين البياض بشكل كبير، ولكن يجب الانتباه إلى قضايا السلامة والبيئة أثناء عملية المعالجة.

6. إضافة المواد المضافة

إن إضافة كمية مناسبة من عامل التبييض مثل ثاني أكسيد التيتانيوم أثناء الإنتاج يمكن أن يحسن البياض. ومع ذلك، لتجنب التأثيرات السلبية على أداء المنتج، يجب التحكم في الجرعة.

ملخص

يعتبر بياض كربونات الكالسيوم مؤشرا مهما لقياس جودتها، ويؤثر إلى حد ما على تطبيق وحصة كربونات الكالسيوم في السوق.

كما ذكر أعلاه، يمكن للطريقة الفيزيائية تحسين بياض كربونات الكالسيوم، أي من خلال الطحن والتصنيف، باستخدام المطحنة والمصنف لمعالجة كربونات الكالسيوم بشكل ناعم. شركة تشينغداو إبيك لآلات المساحيق المحدودة تحتوي على مجموعة متنوعة من معدات المعالجة العميقة للمساحيق، بما في ذلك: مطحنة نفاثة، مطحنة تأثيرية، مطحنة كروية، مطحنة الأسطوانةل، مصنفات مختلفة ومجموعة متنوعة من معدات تعديل طلاء السطح. ومن بينها، مطحنة الكرات و مُصَنِّف مناسبة لطحن وتصنيف كربونات الكالسيوم بشكل ناعم، وبالتالي تحسين البياض.

إذا كان لديك أي مطالب أو أسئلة ذات صلة، فلا تتردد في الاتصال بنا ملحمة تشينغداو، فهم متاحون دائمًا.