Calcium carbonate is an inorganic compound with the chemical formula CaCO₃. It is the main component of limestone and marble, etc. Calcium carbonate is usually white crystals, odorless, and it is widely used in industries of construction, plastics, paper-making, rubber, etc.

In practical applications, in order to meet different requirements of fineness and purity for different uses, calcium carbonate usually needs to be ground and graded before use.

The whole process of calcium carbonate powder processing generally includes the following steps:

1. Raw material collection

The main raw material of calcium carbonate is limestone, and it is a rock containing a large amount of calcium carbonate. In the raw material preparation stage, limestone needs to be obtained from quarries, and preliminary screened to remove impurities, such as gangue.

2. Crushing and grinding

Crushing

Send the selected limestone to the crusher for crushing. Crusher usually includes jaw crusher, impact hammer crusher, etc., they can crush large limestone into small pieces suitable for grinding.

Grinding

Send crushed pieces of limestone to a mill for fine grinding. Commonly used mills include: Raymond mill, ball mill, roller mill, etc. These mills can grind limestone particles into fine powders to meet different requirements for particle sizes.

3. Classifying

The fine powder of calcium carbonate after grinding needs to be classified. Classifying equipment usually includes air classifier, cyclone separator, etc. They can separate fine powders according to particle size to obtain products that meet the requirements.

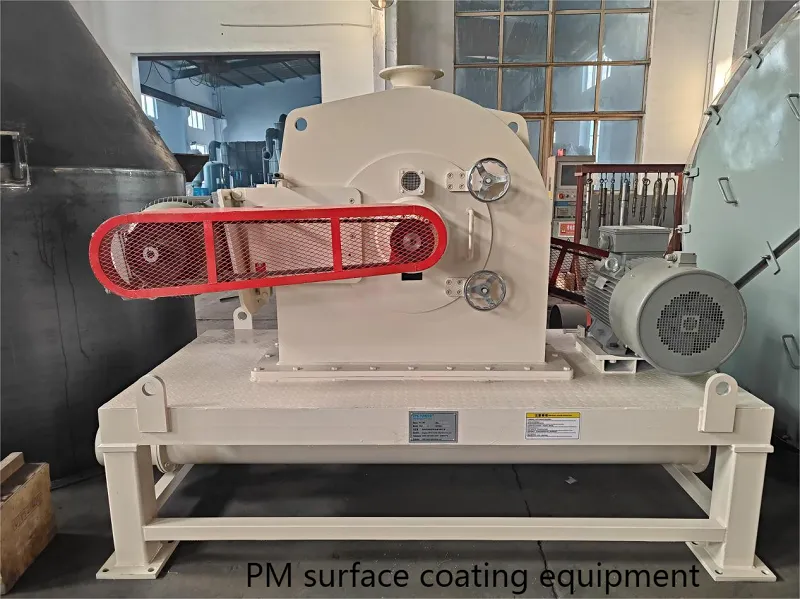

4. Surface coating (optional)

In order to improve the performance of calcium carbonate in different application fields, it is sometimes necessary to perform surface coating on classified calcium powder. Commonly used modifying equipment includes: pin-mill modifier, three-rotor-mill modifier, etc.

5. Packaging

After classifying and surface coating, calcium carbonate powder needs to be packaged. Packaging equipment usually includes: automatic bag filling machine, powder packaging machine, etc. They can put products into packaging bags for easy transportation and sales. During storage, pay attention to moisture and sunlight protection to avoid affecting product quality.

Qingdao Epic Powder Machinery Co., Ltd is a manufacturer specializing in the production of powder processing equipment. Our company has been engaged in the production of powder processing equipment for more than ten years, with rich experience and technical support.

OUR PRODUCTS INCLUDE:

Mill: ball mill, roller mill, air classifier mill, jet mill, turbo mill etc.

Air classifier: HTS, ITC, CTC, TDC, and MBS, totally 5 types.

Surface coating equipment: pin-mill modifier, three-rotor-mill modifier, turbo-mill modifier.

Related auxiliary equipment: PLC cabinet, bag filter, bucket elevator, etc.

If you have relevant demands for powder processing equipment, or want to know more details, please feel free to contact our staff directly, we are always here for you.